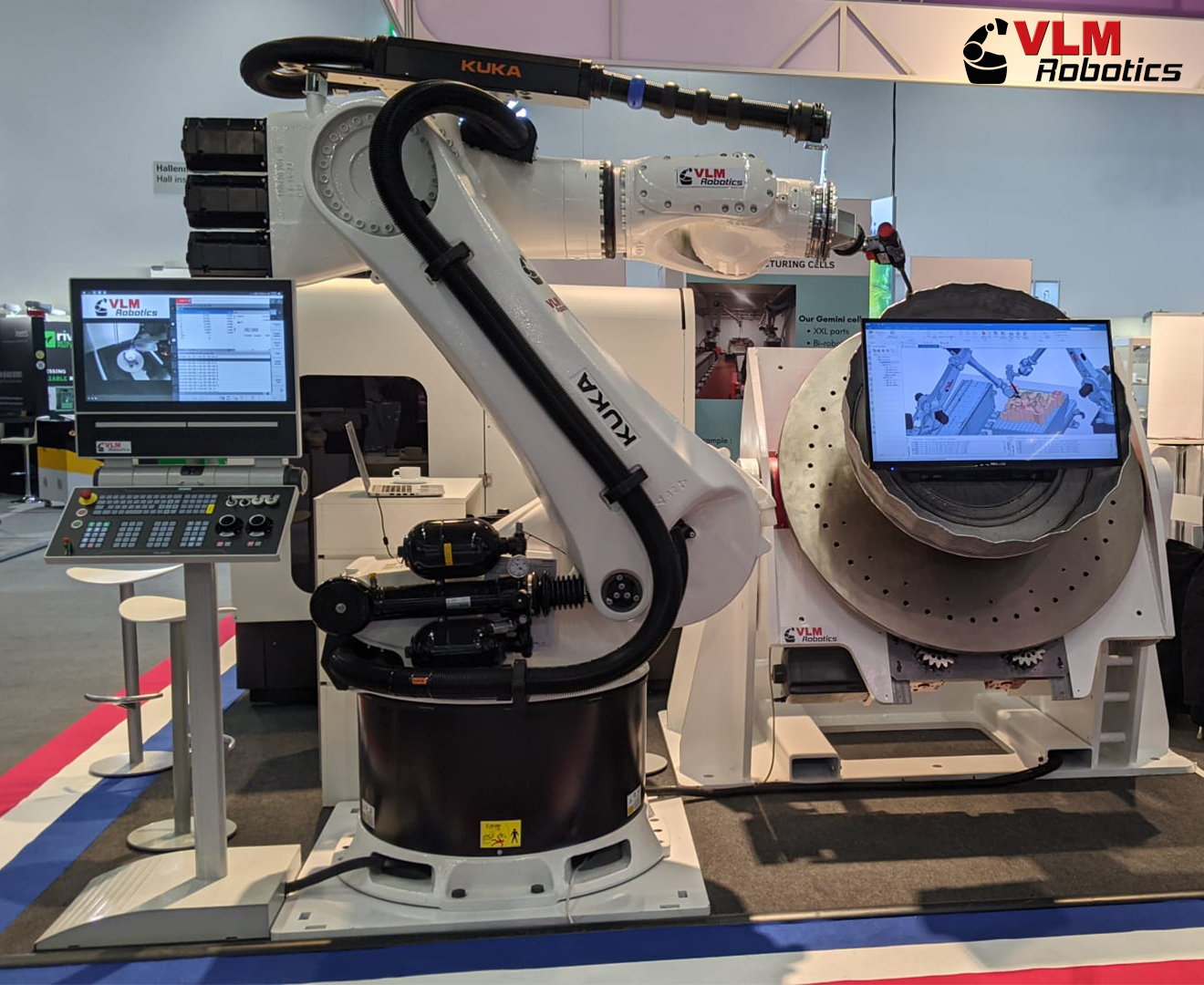

Builder of CNC Robot Hybrid Manufacturing Machines for Production of XXL and High Tonnage Parts

Our models: COMPAQT (XL parts), SOLO and GEMINI (XXL parts), CALISPO (new AMR)

What ?

On all our machines, your turnkey hybrid solution (additive manufacturing, control and subtractive manufacturing) thanks to a full digital thread to finish your industrial part on the turning table!

Digital thread based on : CAE, CAD,CAM, Digital Twin of the machine, CNC, Closed Loop Manufacturing (more than control : adapt the process in real time), Industrial Edge (dash board and data analyse tools) and at the end : Digital Twin of the parts (for the complete history of the part manufacturing)

Further industrial advantages of our machines:

- Agility manufacturing: unit part production or repairing without the need for series

- Traceability: respect of the part’s manufacturing recipe for part qualification

- Industrial maintainability: as machine tool maintainable by your services + remote diagnosis

- Scalability on

- part dimensions and weights up to L :10 m, ϕ :3 m and 20 t

- multi-technologies: introduction of complementary technologies for ALM (LMD, Cold spray …), scan, control in process, NDT in process, texturing …

- additional robots to upgrade for example SOLO to GEMINI

- additional axes; customised length of linear axes (horizontal or vertical for robot or for the part) or portal

- mobilityor maintenance on site with our AMR CALIPSO.

Why ?

To allows you to respond to mass customization demand that is becoming widespread in all sectors, by making it possible to produce your unique parts right the first time as well as your fragmented series. This agile manufacturing delivers you sustainably freeing their competitiveness.

How?

- Expertise and reference on all ALM processes (WAAM, LMD-p, LMD-w, Cold spray) on HYBRID solution (scan, milling, NDT control)

- Robot Machine Tool builder

- Combining the performance of direct control (precision and real-time processing of information)

- Already prepared to operate in multi-channel (to make for example ALM + Milling or ALM and Control at the same time)

- Other hardware features: turning table with backlash compensation, cooling table and 7e axe on the robot for accuracy, local accuracy in closed loop...

- Other automation features: automatic calibration, automatic TCP …

- CNC Sinumerik One : its own programming capacity and its ability to open multichannel programming

Program checking thanks of the machine Digital Twin

Specific process instrumentation on thermal camera, sensor on gas, acoustic or effort measurements ... in adequation with the process chosen

- Closed Loop Manufacturing in process (CLM ™), means process adaption in real time in function of data feedback. Regulation before deviation on CNC

- NX software: module DED technology + Robot module

- Methodologies: to choose the right combination of above elements, to program and drive in function in real time to achieve the goal to produce a good part

- Customer Assistance to support you all the time where you face new industrial challenges.

![]()