Find instead of search – our market directory offers a comprehensive overview of providers, suppliers, manufacturers and the latest solutions and products for Additive Manufacturing with detailed profiles of all Formnext exhibitors.

LEGOR GROUP SPA

About us

Legor is a multinational group founded in Italy in 1979, specializing in the transformation of metals into high-quality alloys, plating solutions, and premium powders for the production of jewelry and fashion accessories.

Today, Legor is among the few companies capable of certifying that its products are made exclusively with precious metals (Gold, Silver, Platinum, Palladium, and Rhodium) sourced from 100% recycled materials, with a fully documented Chain of Custody. Additionally, Legor can now ensure that certain non-precious metals (Silicon, Tin, Indium, Cobalt, Gallium, Germanium, and Copper) are 100% recycled for products related to the UNI EN ISO 14021:2021 certification obtained in October 2022.

Based in Bressanvido (Vicenza), Legor has more than 200 employees, 2 sales offices in Italy, 9 branches worldwide, and over 30 distributors.

Starting from 2024, Legor has adopted a holistic approach to its products: rather than offering products individually, it focuses on providing integrated solutions. This includes offering optimal combinations of alloys paired with meticulously designed plating solutions to meet the distinct needs of the jewelry and fashion sectors. While the quality of its products is undoubtedly crucial, what truly sets Legor apart is its profound expertise and commitment to solving any problems that may arise during the application and processing of its products. This dedication is exemplified through its comprehensive support service, ensuring proximity to customers and guiding them at every stage of the process, thus reinforcing its ethos of responsibility, sustainability, and customer care combined with its specialization in the science of precious metals and innovation.

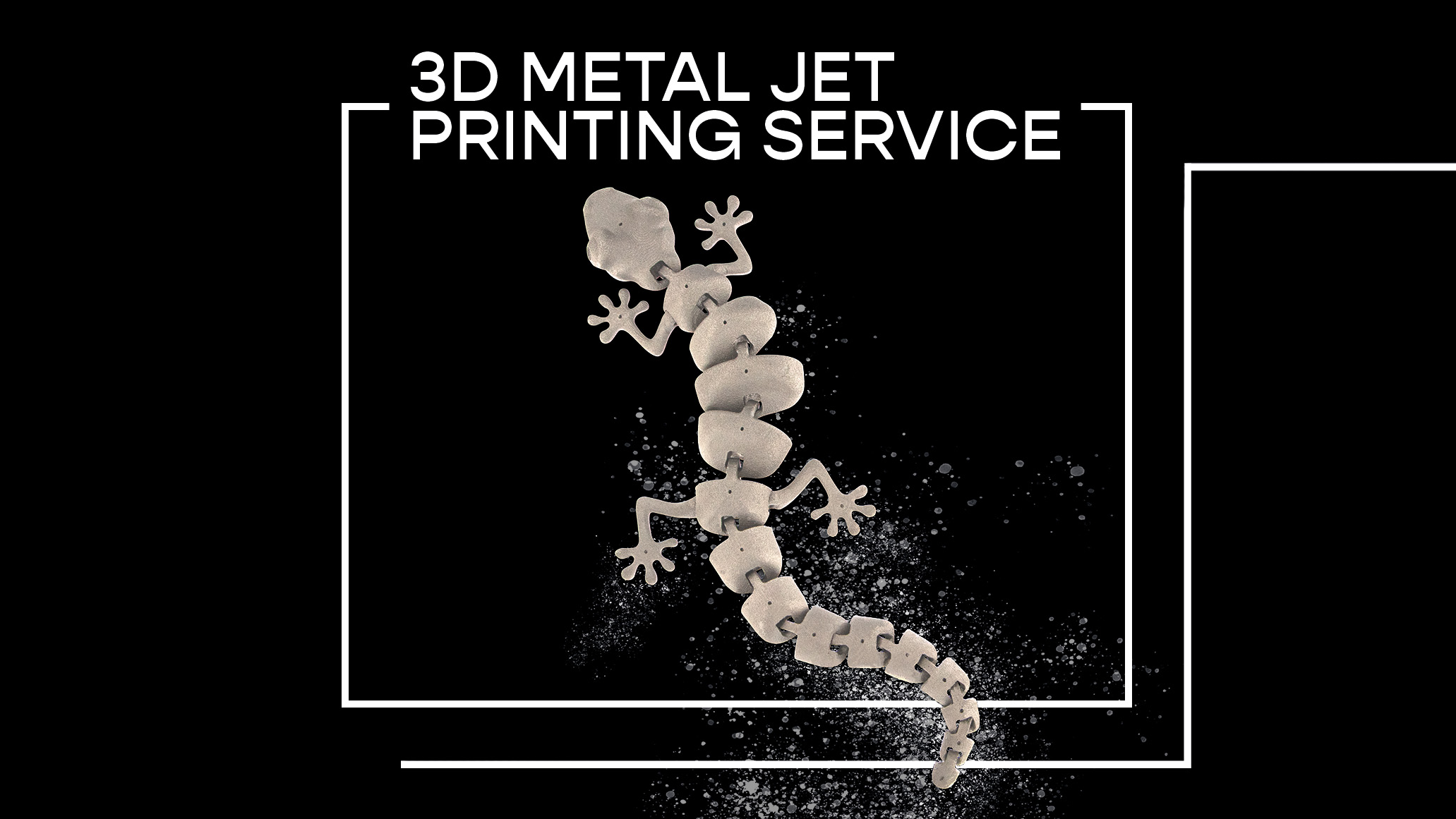

Legor considers innovation as one of its strategic drivers, constantly seeking cutting-edge ideas through the work of its R&D laboratories. In recent years, the drive for progress, innovation, and sustainability have merged to create the Legor 3D Metal Hub: an innovative center aimed at experimenting and producing jewelry, fashion accessories, and industrial parts using metal powders and the revolutionary Binder Jet technology.

Through collaborations with leading industry players, Legor is the first company to introduce this new technology and make the benefits of additive manufacturing available for the development of new solutions in various sectors, combining flexibility and creativity with productivity optimization. With the 3D Metal Jet Printing Service offered by Legor, customers can use this Binder Jet printing technology for a variety of projects in different sectors, including jewelry and fashion accessories production, as well as the manufacture of various industrial components.

At the 2024 edition of Formnext, Legor will showcase the innovation of the 3D Metal Binder Jet printing service, particularly highlighting the significant benefits of this technology, which represents an alternative to other additive manufacturing technologies:

- No need for molds

- Rapid realization of sampling

- Production of multiple parts, even different parts, during the same cycle

- Zero waste - reusable powder at the end of the cycle

- Production of concatenated or hollow objects without welding

- No support required in printing

- Mass customization

Since the experiments began, Legor has enabled the 3D printing of components in steel powder, bronze powder, and has added precious metal powders such as silver and, new this year, platinum. Leveraging the capabilities of 3D Metal Binder Jet technology, Legor is setting new standards in the luxury and high-end jewelry sectors, maximizing the prestigious properties of platinum while overcoming the traditional barriers associated with its manufacturing.

Furthermore, to meet the needs of customers who wish to adopt additive manufacturing with metal powders in their business, Legor has developed a dedicated line of powders: Powmet. This is in line with offering always integrated solutions that satisfy every phase of product realization.

Keywords

- precious metal powder

- powders for 3D manufacturing

- Binder Jet technology

Our Products

Legor 3D Metal Jet Printing Service

Legor is the first Italian company to introduce the revolutionary Binder Jet technology as a full-fledged production opportunity and to provide an exclusive additive printing service for the development of new solutions in various sectors, from the jewelry world to the fashion accessory industry - Legor's core business - to potential applications in the automotive, aerospace, and electronics industries.

Ideally, the entire manufacturing sector can benefit from the potential of Legor's 3D Metal Jet Printing Service:

- rapid prototyping

- production of parts with complex geometries

- reduction of material waste and associated costs

- the possibility of printing parts with different functions in a single object - thus reducing the need for assembly

- cost savings for complex parts or low volumes

- greater sustainability, through the reuse of up to 99% of the powder

What makes Legor's printing service even more unique are the metallic powders used as the starting material. Currently, Legor can produce and print objects in steel, bronze, 925 silver, and, new for this year, with precious platinum 950 powder. The next step will be printing with 18-carat gold powder.

Furthermore, to meet the needs of 3D printing and its future adoption on a large scale, Legor has developed Powmet, a line of metal powders with fine and homogeneous particle size specific to 3D printing technology.

Platinum 950 powder for additive manufacturing

3DBJ-PTRU is a Platinum 950‰, Ruthenium based, proprietary alloy powder from the high-quality Powmet line, developed specifically for additive manufacturing processes. Primarily created for 3D binder jetting, this alloy powder is the result of cutting-edge technologies and develpoed by one of our R&D projects dedicated to powder metallurgy for additive manufacturing applications.

More info about chemical composition, physical properties and size distribution available on request.

Platinum 3D printing through 3D Metal Jet Printing Service

Thanks to the potential of 3D Metal Binder Jet Technology, Legor is setting new standard in the luxury and jewelry sectors by maximizing the unique properties of platinum.

The introduction of 3D Metal Binder Jet technology to the world of jewelry and high-end watchmaking has revolutionized the processing of platinum, overcoming many challenges associated with its fabrication. Unlike traditional manufacturing techniques, 3D printing technology does not require physical manipulation of the metal, eliminating common difficulties associated with its processing and allowing for the direct creation of complex platinum designs that would otherwise be impossible or prohibitively expensive to produce using conventional methods.

Learn more on our website or ask for more information