Sehen Sie, wer alles dabei ist oder erstellen sich Ihre eigene Merkliste. Nutzen Sie die Filtermöglichkeiten, um eine Ausstellerliste zur jeweiligen Produktgruppe zu erhalten.

Beschreibung

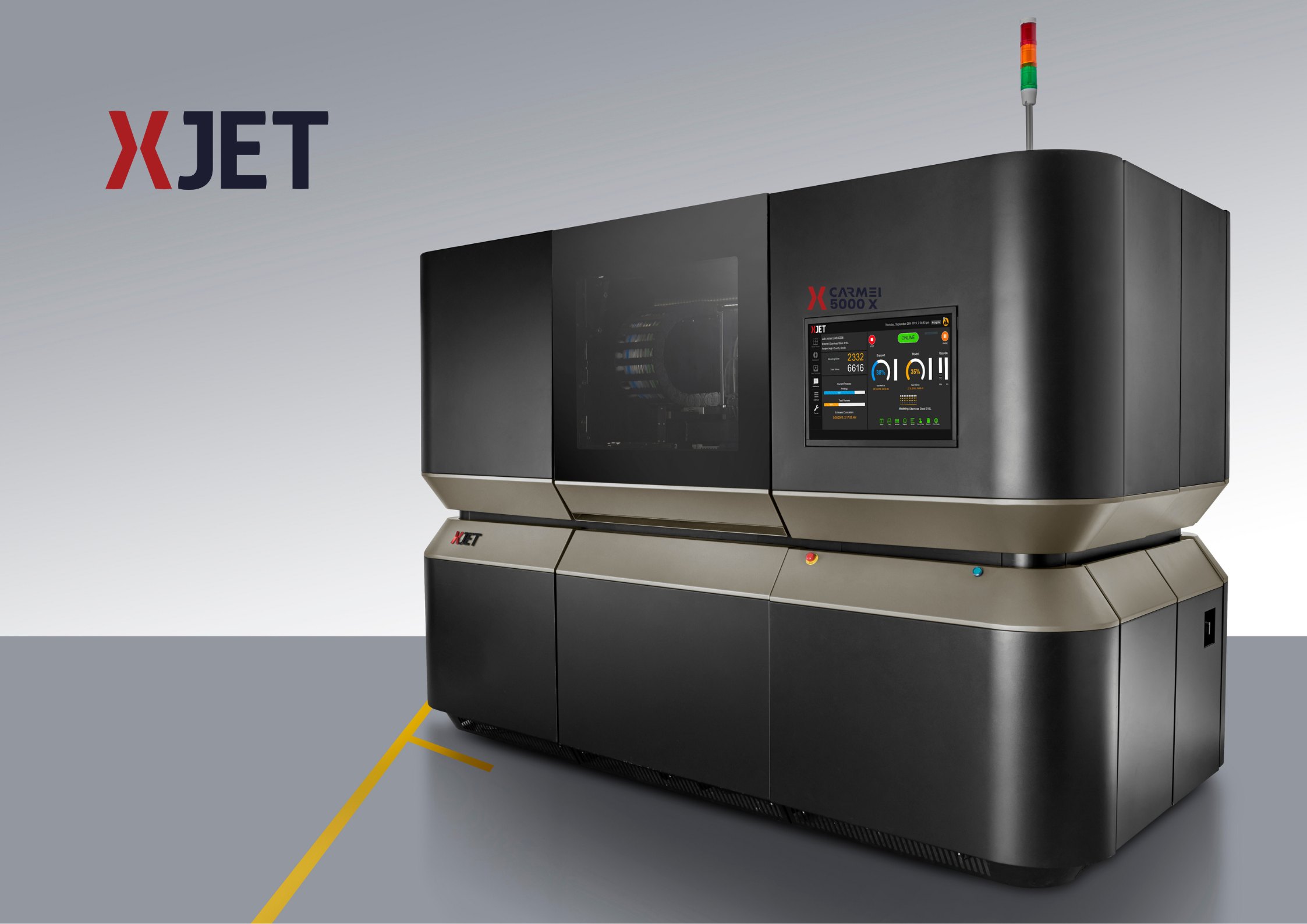

CARMEL 1400C – CERAMIC AM SYSTEM

The XJet Carmel 1400C deliver unrivaled quality, accuracy and repeatability to your applicational parts, with high productivity when it is needed the most.

From health care to industrial applications, the XJet Carmel 1400C can fit your needs, either in part complexity or high productivity.

Now you can do both at the same time with no compromise.

Unlashing the power of powderless Nano Particle Jetting™ (NPJ) technology

The XJet Carmel 1400C leverages XJet’s revolutionary, patented process to produce parts with unprecedented smoothness, details & density. NPJ inkjet technology enables the production of ceramic AM parts in materials you're familiar with (starting with Zirconia & Alumina), but with the advanced complexity and high requirements needed for today's manufacturers.

Industry first nano particle jetting technology enable highest density up to 100% with no comprise on details, part smoothness and best in class accuracy.

System

Build volume

500 x 280 x 200 mm; 19.7 x 11 x 7.9 inch; Removable

Material loading

Fully enclosed Build and Support ink cartridges

Layer thickness

5-10 microns

Building speed

Up to 1.5mm height per hour

Embedded O/S

Windows 7 or higher, 64-bit

Network connectivity

LAN – TCP/IP

Software package

Autodesk® Netfabb® Ultimate with remote view with mobile app.

User Experience

Touchscreen

Dimensions

310 x 212 x 185 cm; 122 x 83 x 72 Inch

Weight

3 Tons; 6614 LB

Electrical power

EU: 400 VAC; 3 Phases; 3 x 30A; 50/60 Hz

US: 208 VAC; 3 Phases; 3 X 50A; 60Hz

Air pressure required

7Bar

Environment operation

18° - 25°C; 64° - 77°F

Regulations conformity

CE; FCC; UL – In process

Materials

Materials

Zirconia, Alumina, Soluble support

Shelf life

Up to1 year under recommended conditions

Safety

MSDS available per material

Part Properties1

Accuracy2

Up to 50 microns

Minimum feature size

200microns

Density

Zirconia - 6.04 g/cm³ (>99.9%)

Alumina - 3.96 g/cm³ (>99.5%)

Tensile Strength3

Zirconia - 520 MPa

Alumina – 430 MPa

Surface roughness

N8-N9

Shrinkage

Linear & Isotropic;

Zirconia - 12.9% per dimension

Alumina - 15.4% per dimension

Disclaimer: The data included is for information purposes only and should not be considered specific advice to any customer project. The provision of the product described is subject to changes and XJet terms and conditions.

- All measurements are based on internal XJet lab testing made on lab specimens

- Depending on geometry, build parameters and model orientation

- Measured according to ASTM A240