Sehen Sie, wer alles dabei ist oder erstellen sich Ihre eigene Merkliste. Nutzen Sie die Filtermöglichkeiten, um eine Ausstellerliste zur jeweiligen Produktgruppe zu erhalten.

Beschreibung

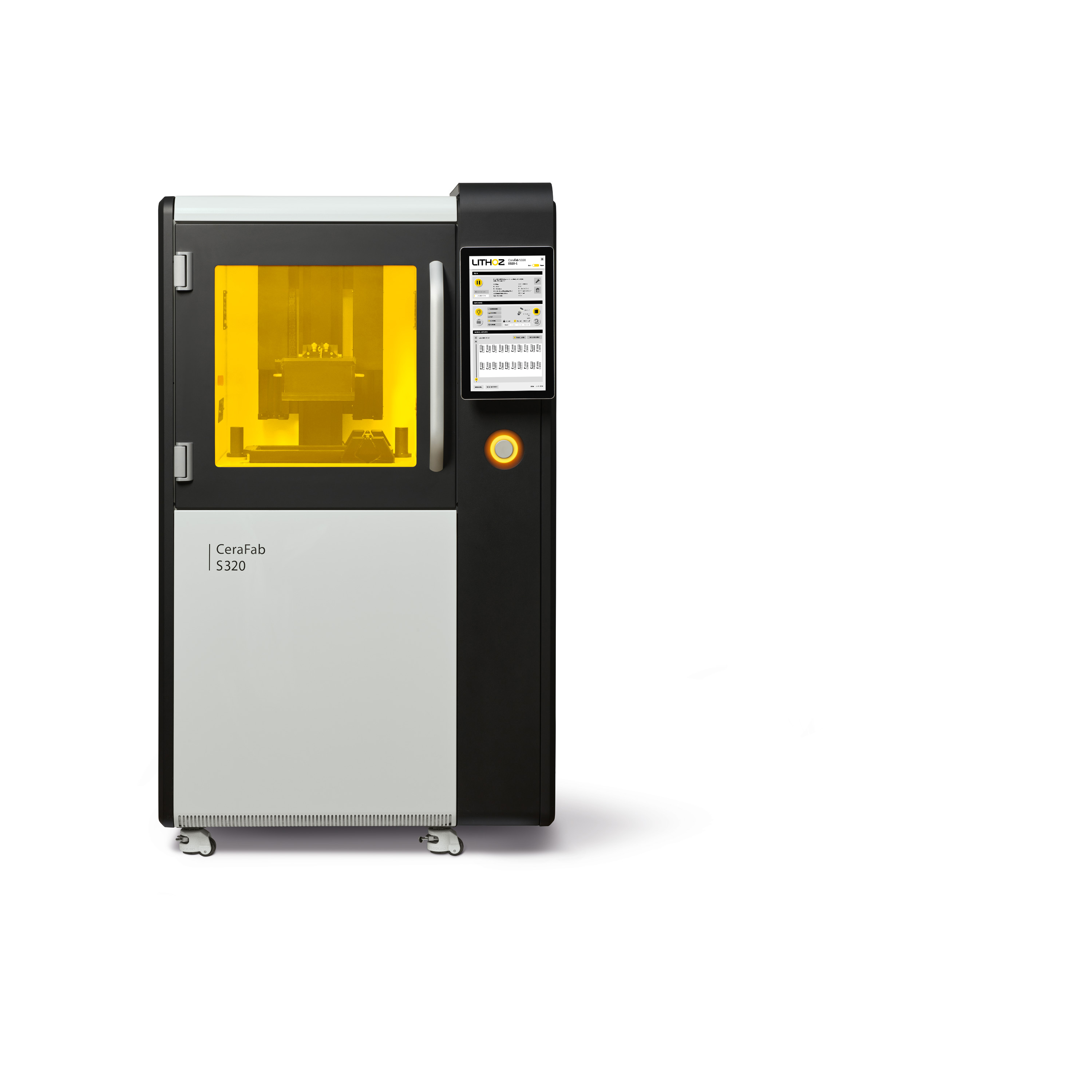

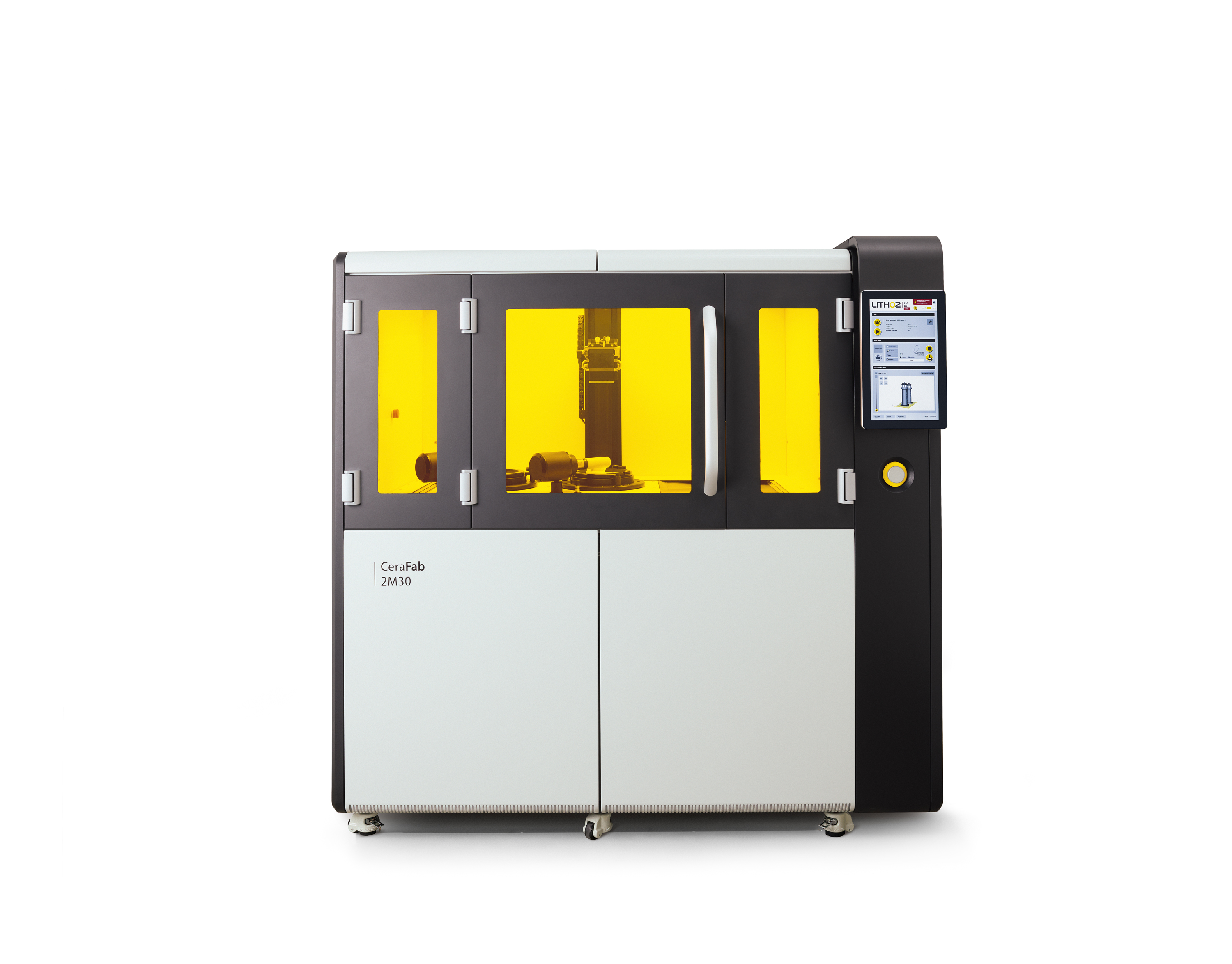

CeraFab System S320 – LCM-Drucker mit hohem Durchsatz für mittelgroße Keramikkomponenten

Das CeraFab System S320 ist die neueste Weiterentwicklung der LCM-Plattform (Lithography-based Ceramic Manufacturing) von Lithoz, die speziell für die industrielle Fertigung von mittelgroßen technischen Keramikkomponenten entwickelt wurde. Mit einer fünfmal größeren Bauplattform als das S65 ist das S320 für die Serienfertigung optimiert und bietet eine unübertroffene Produktivität bei gleichbleibend hoher Auflösung über eine größere Fläche.

Wichtigste technische Merkmale1. Bauvolumen und Durchsatz

- Bauvolumen: 246 x 130 x 320 mm→ ~5× größer als das S65, was eine deutlich höhere Teileausbeute pro Bauauftrag oder den Druck viel größerer Komponenten ermöglicht

- Außenabmessungen: identisch mit dem S65, sodass eine direkte Integration in bestehende Produktionslinien ohne zusätzlichen Platzbedarf möglich ist

- Schichtgeschwindigkeit: bis zu 150 Schichten/Stunde, gleich wie beim S65, jedoch mit deutlich höherem Teiledurchsatz pro Durchlauf

2. Optisches System und Auflösung

- Projektionssystem: 4K-UV-Projektor (405 nm Wellenlänge)

- XY-Auflösung: Bis zu 60 μm über den gesamten Baugebiet

- Schichtdicke: Einstellbar zwischen 20–200 μm, ermöglicht je nach Anwendung einen flexiblen Kompromiss zwischen Präzision und Geschwindigkeit

- Im Vergleich zum WQXGA-Projektor des S65 gewährleistet die 4K-Optik des S320 eine gleichbleibend hohe Auflösung über einen wesentlich größeren Belichtungsbereich und unterstützt sowohl feinere Details als auch breitere Geometrien

3. Wärmemanagement

- Integriertes Zweikammer-Heizsystem: Sorgt für eine stabile und gleichmäßige Temperaturverteilung über die große Bauplattform und gewährleistet so Materialhomogenität und zuverlässige Schichtverbindung

- Vorteil gegenüber dem S65: Dieses Zweikammer-Design verbessert die Temperaturregelung bei größeren Bauprojekten, bei denen die Wärmeverteilung für die Prozesskonsistenz entscheidend ist

4. Materialhandhabung und Druckkontinuität

- Zwei automatische Dispenser (2 × 650 g): Ermöglichen längere, unterbrechungsfreie Druckaufträge, ideal für den Nacht- oder Mehrschichtbetrieb – eine Verbesserung gegenüber der Einzelzufuhrkonfiguration der S65.

- Präzise Dosierungssteuerung: Hält den Materialverbrauch extrem niedrig, entsprechend der Leistung der S65.

5. Software und Prozesssteuerung

- CeraControl-Softwareintegration für vollständige Systemautomatisierung und Synchronisation zwischen Druckern

- Unterstützt die Vernetzung von bis zu 100 Systemen und ermöglicht so eine synchronisierte, verteilte Produktion über globale Standorte hinweg

- Echtzeit-Prozessüberwachung und Auftragsdokumentation gewährleisten vollständige Rückverfolgbarkeit für Serienfertigungsumgebungen