Sehen Sie, wer alles dabei ist oder erstellen sich Ihre eigene Merkliste. Nutzen Sie die Filtermöglichkeiten, um eine Ausstellerliste zur jeweiligen Produktgruppe zu erhalten.

Beschreibung

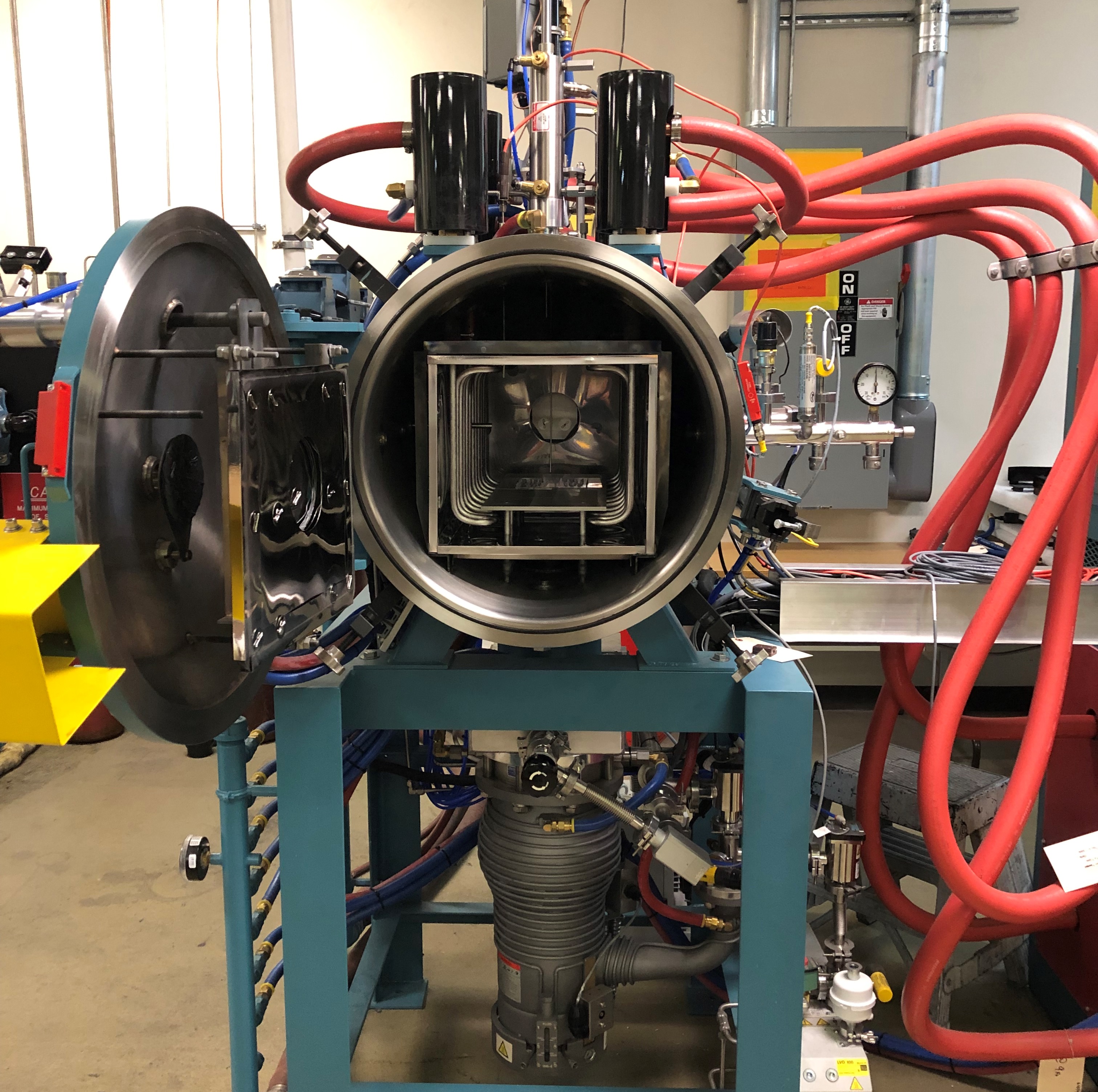

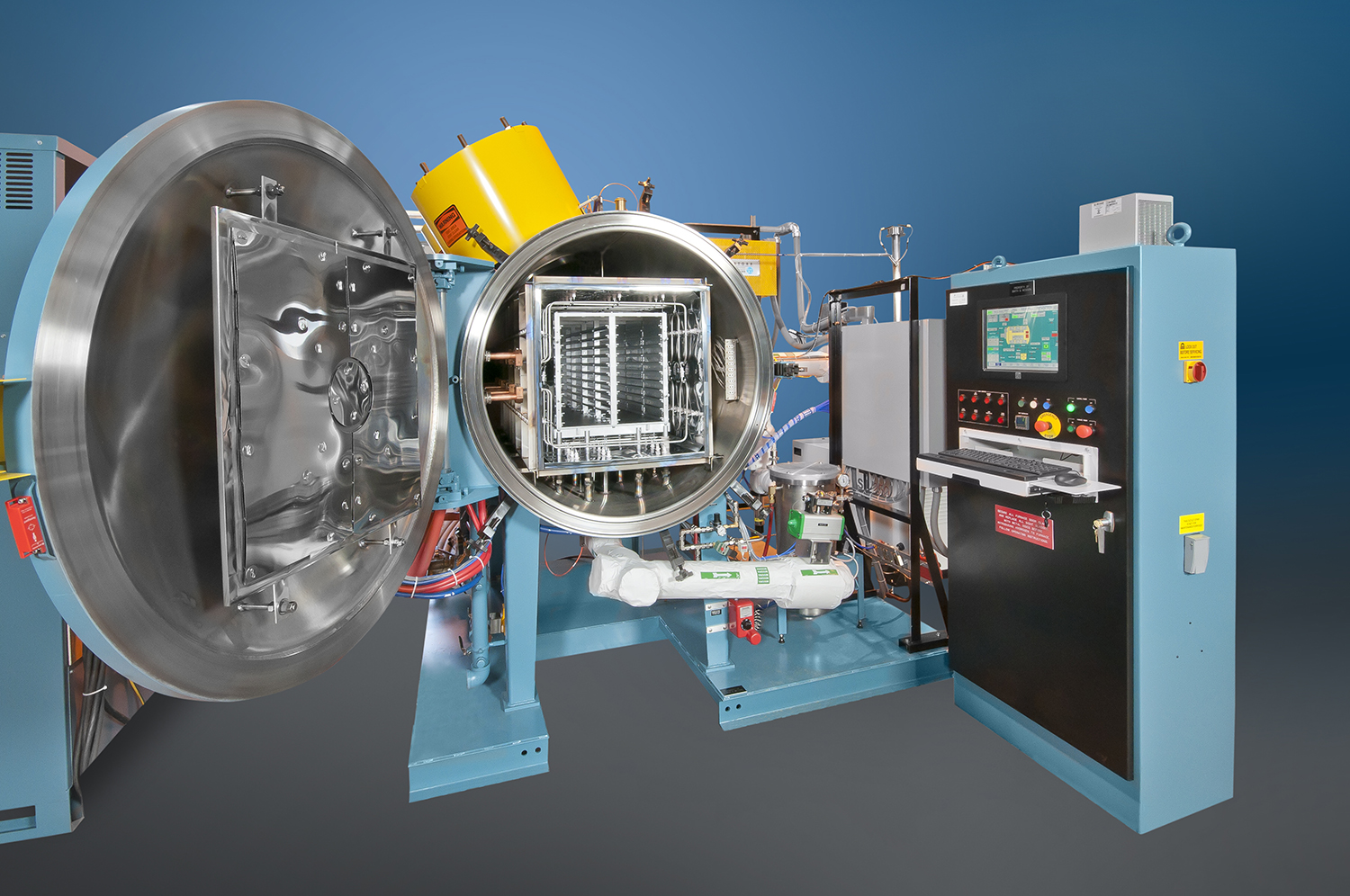

Das Workhorse AM™ ist ein produktionsorientiertes Angebot von Centorr Vacuum Industries, das speziell für die sekundäre Wärmebehandlung, das Glühen, das Spannungsarmglühen, das Entgasen und die Abschreckkühlung von 3D-gedruckten und additiv gefertigten Teilen entwickelt wurde. Da bei den Verfahren DLS (direktes Lasersintern) und SLM (selektives Laserschmelzen) örtlich kleine Stellen innerhalb des gesamten Teils bei hoher Temperatur geschmolzen werden, können sich in den Teilen Mikrospannungen aufbauen, die beseitigt werden müssen, um verbesserte physikalische Eigenschaften wie Ermüdungsfestigkeit, Härte, Haltbarkeit und Duktilität zu erreichen. Das Glühen und Entspannen im Vakuum oder in einer kontrollierten Inertgasatmosphäre sorgt für die notwendige Spannungsreduzierung. Die ultrareine Vakuumumgebung gewährleistet außerdem keine Oxidation oder Entkohlung und eine glänzende Teileoberfläche im Vergleich zur Wärmebehandlung in Kastenöfen mit normaler Atmosphäre. Der Workhorse AM™ verfügt über eine lange Liste optionaler Ausrüstung, die ihn zu einem der vielseitigsten maßgeschneiderten Öfen macht, die heute erhältlich sind. Das Grunddesign besteht aus der Standard-Heißzone mit einer Nenntemperatur von 1315 °C und einem optionalen Upgrade auf 1650 °C für die Verarbeitung höher schmelzender Materialien wie Superlegierungen und Titan. Das Workhorse AM™ verfügt sogar über eine Option für den Betrieb im Überdruck, um bestimmte Legierungen in einer kontrollierten Atmosphäre aus reinem Inertgas zu verarbeiten. Für Anforderungen an eine schnelle Abschreckgaskühlung kann der Ofen mit einem 2BAR-Gasabschreckkühlsystem ausgestattet werden, das aus einem großen Rotationsventilator und einem wassergekühlten Wärmetauscher besteht. Die Ofenkammer ist für ein kompaktes und hocheffizientes Design auf Beinen montiert und weist eine „Frontlader“-Ausrichtung auf, die im Vergleich zu vertikalen Top-/Bottom-Loadern oder zylindrischen Heißzonen eine bessere Ergonomie und Temperaturgleichmäßigkeit bietet.