Text and Images: 3DPrint.com, 2 November 2023

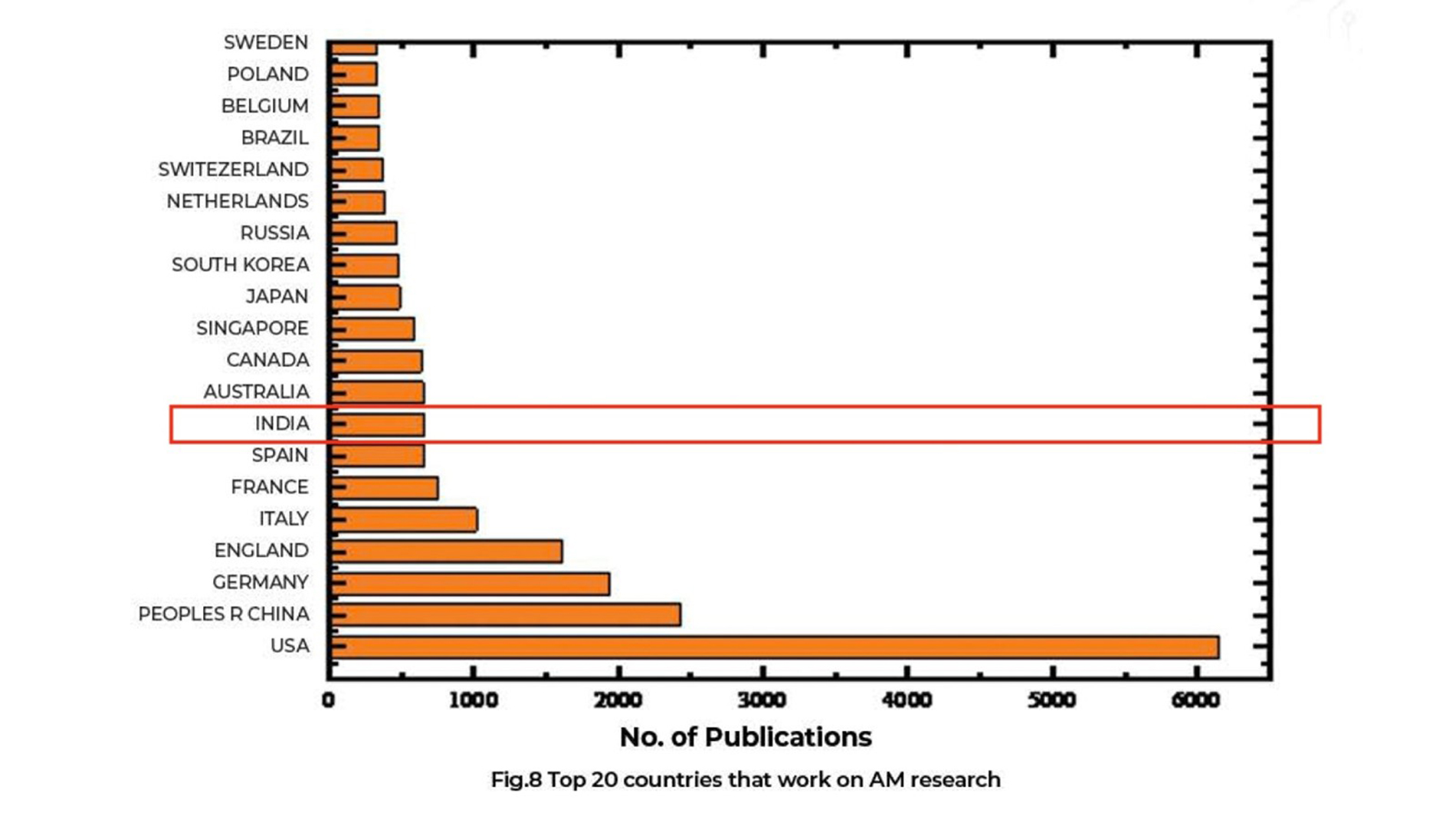

Although countries like the US, Germany, and China have extensively adopted additive manufacturing (AM), India has been slower to do so. Nonetheless, the potential of AM to propel socio-economic growth has caught the attention of the Indian manufacturing ecosystem. This article will explore the historical trajectory of AM in India, the national 3D printing strategy, sectoral focus, and use cases.

Historical Trajectory of AM in India

From its nascent stages to its burgeoning presence today, India’s journey in 3D printing is a testament to its adaptive capabilities and forward-thinking approach.

1) The Early Days (1990s – 2000s):

The first instances of AM in India can be traced back to the late 1990s when global industries started exploring rapid prototyping. During this period, a few Indian companies and educational institutions began importing 3D printers, primarily for research and prototyping. The Indian Institute of Technology (IIT) Bombay was among the pioneers, setting up an AM lab to explore the potential of this novel technology.

2) The Rise of Domestic Manufacturers (2000s – 2010s):

By the mid-2000s, India saw the emergence of its first domestic 3D printer manufacturers. Firms like Divide By Zero and Altem Technologies began offering indigenously developed 3D printers, challenging the market dominance of imported machines. These machines, primarily employing fused deposition modeling (FDM), catered to the growing demand from educational institutions and small-scale industries.

3) Expanding Horizons (2010s):

The 2010s marked a significant turn in India’s AM journey. The country witnessed a surge in startups dedicated to 3D printing, offering services ranging from prototyping to finished product manufacturing. Companies like Imaginarium, Think3D, and Sahas Softech made notable strides in the industry. This period also witnessed the emergence of metal 3D printing in sectors such as aerospace, healthcare, and automotive.

The Government of India, recognizing the potential of AM, launched initiatives under the ‘Make in India‘ campaign to promote indigenous manufacturing and R&D in 3D printing. The establishment of the Centre of Excellence in Additive Manufacturing (CoE-AM) at IIT Hyderabad in 2017, in collaboration with Applied Research International, was a significant step in this direction.

4) The Surge of Industrial Applications (2020s):

The most recent years marked a key shift in India’s AM journey. The decade witnessed the rapid adoption of 3D printing across various industries, propelled by technological advancements, decreasing costs, and a growing comprehension of AM’s potential.

The Blueprint: India’s National AM Strategy

The Ministry of Electronics and Information Technology (MeitY), being a nodal agency for Digital Technology, has evolved a strategy to promote all the verticals of the AM sector, including machines, materials, software, and designs to leverage the untapped business opportunities in this emerging technology that will unfold in the near future.

1) National Strategy for AM:

India’s National Strategy for Additive Manufacturing is geared towards building a resilient ecosystem that attracts global AM expertise and fosters local adoption. This aligns with the ‘Make in India’ and ‘AtmaNirbhar Bharat Abhiyan’ initiatives, seeking self-reliance through 3D printing. The primary focus is on enhancing domestic production, reducing imports, and promoting innovation. To achieve these goals, India is investing in advanced AM technologies, ensuring the economic stability of its 3D printing sector, and aiming for technological leadership.

2) Strategic Milestones:

The National Strategy aspires for India to carve out a 5% stake in the global AM market, with the aim of contributing nearly US$ 1 billion to the GDP by 2025. The targets encompass:

- Fostering 100 innovative start-ups in AM.

- Developing 50 India-centric AM technologies.

- Positioning India as a prime hub for 3D printed design and manufacturing.

- Amplifying AM awareness across 500 diverse sectors.

AM Landscape in India

1) Government Initiatives:

- 3D Printing Lab: The National Institute of Electronics & Information Technology, Aurangabad, has established a 3D printing lab and offers certification courses in 3D printing.

- Atal Innovation Mission: Under this mission, Atal Tinkering Labs have been set up and equipped with modern technologies, including 3D printers. Students are encouraged to innovate using these resources.

- MoU with US Institute: The Gujarat government has partnered with the US Institute of 3D Technology (USI3DT) and 3D systems to create seven 3D printing Centers of Excellence in engineering colleges nationwide.

- 3D Bioprinting Lab: A collaboration between Andhra Pradesh MedTech Zone and the University of Wollongong has led to establishment of a 3D Bioprinting Lab.

- The National Centre for Additive Manufacturing (NCAM) has been established by the Ministry of Electronics and Information Technology (MeitY) in partnership with the Government of Telangana and industry at large. NCAM aims to create a sustainable ecosystem for product innovation, establish a comprehensive ecosystem for AM adoption in industries, facilitate cutting-edge technologies, guide policy improvements, empower major firms in AM adoption, foster innovation and promote skill training activities to generate a talented workforce.

2) Private Sector Initiatives:

- INTECH Additive Solutions: Based in Bengaluru, INTECH is a leader in metal 3D printing in India. They have developed software for AM, designed India’s first metal printer, and launched a digital academy for AM training.

- Ace Micromatic Group: Their AMACE Solutions wing unveiled their latest large-format laser powder bed fusion machine, the ALM- 400, at IMTEX 2023. The machine boasts a 410/410/450mm build volume, 1Kw laser power, and other patented features. It’s worth noting that Ace Micromatic Group is currently India’s largest machine tool conglomerate.

- Wipro: The company introduced ‘Addwize,’ a program aimed at helping organizations adopt and scale metal AM use for business advantages.

- AM Chronicle: AM Chronicle is a renowned information and content platform for the AM industry in India. AM Chronicle is the media vertical of the Indian 3D Printing Network.

3) Collaborative Efforts:

- COE at IISc Bengaluru: The Department of Heavy Industries collaborated with Wipro to create India’s first industrial-grade 3D printer.

- HP Inc: An MoU was signed with the Andhra Pradesh government to build a 3D printing Centre of Excellence.

- Stratasys and NTTF: They have launched India’s first AM certification course to bridge industry skill gaps.

4) Academia and Research:

Various esteemed institutions in India are currently utilizing AM technology, including:

- International Advanced Research Centre (ARC), Hyderabad (techniques: SLM, OED)

- Defence Metallurgical Research Laboratory (DMRL) (technique: LENS)

- Raja Ramana Centre for Advanced Technology (RRCAT), Indore (technique: LENS)

- Central Mechanical Engineering Research Institute (CMERI), Durgapur

- Central Glass and Ceramic Research Institute (CGCRI), Kolkata (technique: SLM)

- Central Electrochemical Research Centre (CECRI), Karaikudi

- Central Manufacturing Technology Institute (CMTI), Bengaluru (techniques: SLM, OED)

- Indian Institute of Technology, Mumbai (IITB) (techniques: wire-LAM, CMTJ)

- Indian Institute of Technology, Hyderabad (IITH) (technique: Wire ARC)

- IIT Kharagpur (technique: SLM)

Furthermore, RRCAT, Indore, and CGCRI, Kolkata, have spearheaded AM research on Ni and Ti alloy components. DMRL has made strides in creating discrete and compositionally varied materials using SS316 and IN625 alloys via the LENS™ process. Additionally, a laser team from RRCAT has innovated an indigenous laser-engineered, coaxial powder-fed AM system, researching several alloys to assess their microstructural and mechanical attributes.

Sectoral Focus of AM in India

1) Electronics:

The electronics sector, a high-volume manufacturing domain, grapples with challenges, causing a disability rate of 8.5-11%. Despite its potential, the adoption rate of AM in electronics remains sluggish. AM techniques in this sector usually deploy material jetting solidified by ultraviolet light using conductive and insulating inks. The Ministry of Electronics and Information Technology has launched initiatives to bolster the domestic electronics landscape.

2) Aerospace:

The Aerospace sector in India is dominated by imports; about 70% of raw materials, including special alloys, and more than 50% of electronic components in satellites. India’s defense sector is gearing up to acquire around 750 aircraft and helicopters. The country’s defense MRO market is predicted to hit $2.5 billion by 2025.

3) Defense:

India stands as the world’s second-largest defense equipment importer. Annually, the defense procurement orders touch an astounding $100 billion. Recent FDI norms have been revamped to permit up to 74% foreign investment in the defense sector.

4) Automotive:

India’s automotive industry, contributing 7.5% to the national GDP, witnessed imports of auto components worth $17.6 billion in 2018-19. As the industry transitions to BS-VI norms, AM technologies present promising benefits. A notable instance includes a premier auto manufacturer in India leveraging Stratasys’ AM technology to save significantly in manufacturing costs.

5) Medical Devices:

A majority of India’s medical device requirements, between 70-90%, are fulfilled through imports. The sector is poised for growth, with projections estimating it to be worth $25-30 billion by 2025. The nation saw a staggering 4,67,044 road accidents in 2018, underscoring medical device needs. Notably, 3D-printed prosthetic limbs are emerging as a cost-effective solution in India.

6) Construction and Architecture:

Recent data from March 2020 reveals cost overruns in 403 infrastructure projects, each exceeding Rs 150 crore. AM has been instrumental in various construction endeavors, from housing to bridge fabrication. A groundbreaking innovation from IIT Madras and a local startup has introduced a technology enabling concrete to solidify in a mere 3-5 hours.

Glimpses of AM Application Across Sectors

1) Aerospace and Defense:

- HAL’s Foray into 3D Printing: Hindustan Aeronautics Limited (HAL) partnered with Wipro 3D to develop a 3D-printed aircraft component, marking a significant milestone in India’s aerospace sector.

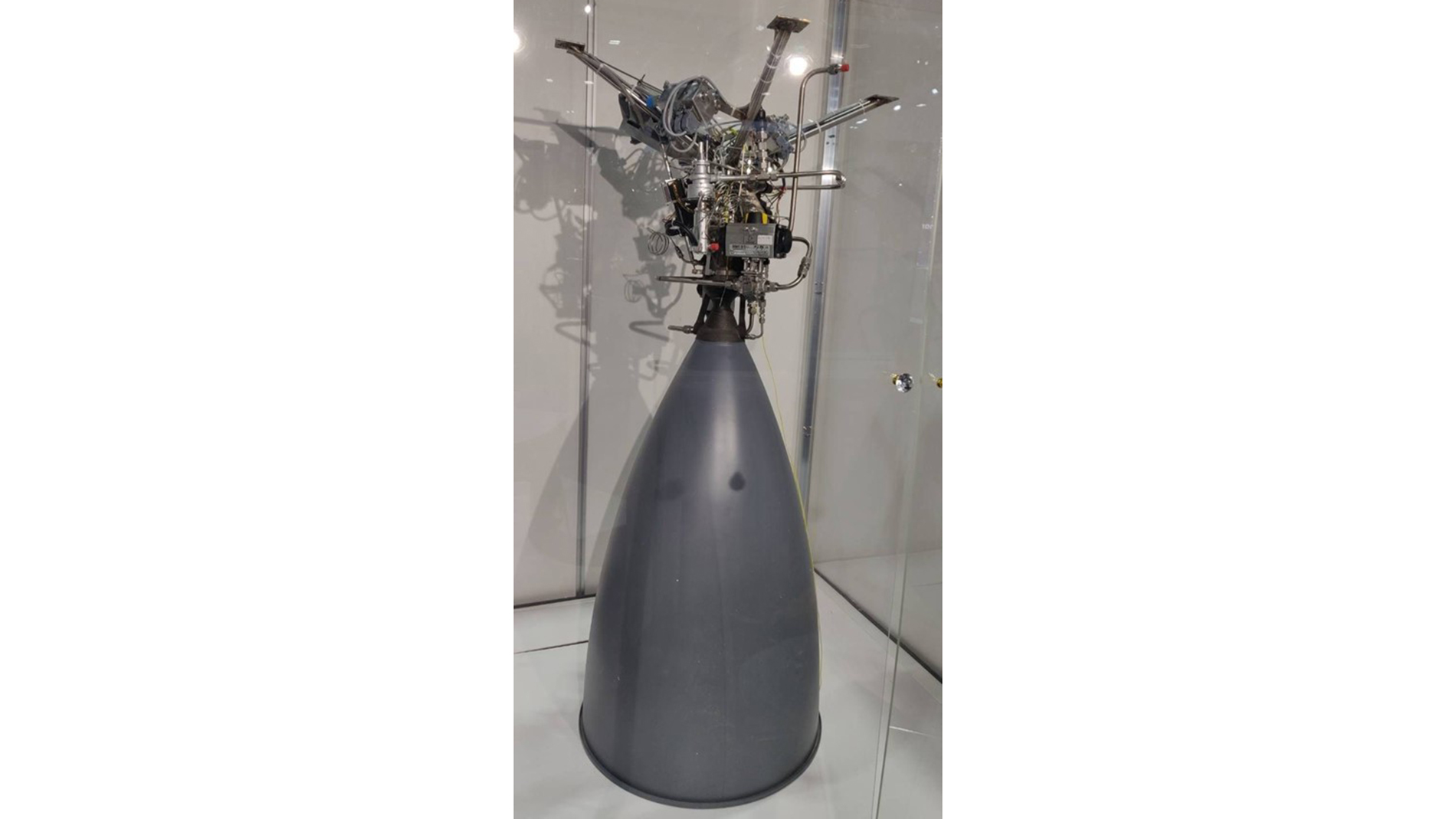

- The first fully 3D printed Rocket Engine: Indian space startup Agnikul Cosmos has successfully tested the world’s first fully 3D-printed rocket engine in 2022, with support from the Indian National Space Promotion and Authorization Center (IN-SPACe) and the Indian Space Research Organization (ISRO). The test validated the technological possibility of creating rocket engines as a single piece of hardware.

Agnikul Cosmos’ single-piece 3D printed engine. Image courtesy of Agnikul Cosmos via Twitter.

2) Healthcare and Biomedical:

- Customized Implants and Surgical Guides: Osteo3D, based in Bangalore, has led 3D printing medical models and surgical guides, assisting surgeons in planning complex procedures, especially in maxillofacial surgeries.

- Bioprinting Innovations: IIT Delhi’s research in 3D bioprinting of tissues resulted in the development of a bioprinted cartilage, heralding a significant advancement in regenerative medicine.

3) Automotive:

- Rapid Prototyping at Mahindra: The Mahindra Group has integrated AM into its design process, streamlining prototype development.

- On-Demand Spare Parts by Tata Motors: Embracing AM for producing spare parts has allowed Tata Motors to reduce inventory costs and improve parts availability.

4) Construction:

- India’s first 3D Printed Security Pavilion: Godrej Construction and IIT Madras start-up, Tvasta, have jointly created India’s first 3D Printed Security Pavilion at the Godrej & Boyce Campus in Mumbai. Using a Robotic Arm 3D Printer, the innovative structure demonstrates the future potential of 3D printing in construction.

- World’s first 3D printed temple: Apsuja Infratech and Simpliforge Creations are constructing the world’s first 3D printed temple in Siddipet, Telangana. This innovative 3,800 sq. ft temple, showcasing unique Hindu deity designs, highlights the vast potential of 3D printing in architecture. The construction was executed with Simpliforge’s advanced robotic arm system and indigenous materials,

- Kerala’s Debut 3D Printed Building: ‘Amaze 28’, Kerala’s first 3D printed building at PTP Nagar KESNIK campus, was constructed in 28 days and cost Rs 11 lakh. Using Tvasta’s software, this efficient construction method promises faster and more cost-effective building processes. The technology significantly reduces labor and time, potentially shifting traditional construction techniques.

Conclusion

India’s journey in the realm of 3D printing is inspiring and indicative of a promising future. From its modest beginnings in the 1990s to the vast ecosystem that thrives today, India’s AM landscape has been shaped by innovation, strategic planning, and a confluence of public and private initiatives. The strategic alignment with national campaigns, such as ‘Make in India,’ underscores the nation’s commitment to harnessing AM’s economic growth and self-reliance potential. As sectors ranging from aerospace to healthcare embrace AM, India is poised to redefine global manufacturing paradigms. While challenges persist, the nation’s adaptability, visionary mindset, and collaborative spirit signal a future where AM plays a pivotal role in India’s socio-economic fabric.

*This article was originally published on 3DPrint.com on 13 October 2023.

FURTHER INFORMATION:

Tags

- Additive Fertigung