Sika is a specialty chemicals company with a leading position in developing and producing systems and products for bonding, sealing, damping, reinforcing, and protecting in the building sector and manufacturing industry. Sika has subsidiaries in 101 countries worldwide and manufactures in over 300 factories. Its more than 27,000 employees generated annual sales of CHF 9.3 billion in 2021.

Sika solutions for 3D concrete printing

3D concrete printing (3DCP) is a form of cement-based additive manufacturing that produces buildings or structural components in entirely new shapes that were previously impossible with conventional concrete moulds. Sika offers Sikacrete® 3D 1-component and 2-component material solutions for fast, accurate, and cost-effective concrete printing according to your project requirements.

There are numerous types of mixers, pumps, and robotics on the market, and ultimately the equipment and material must work effectively together. All these factors play a significant role in achieving optimal results for the finished concrete.

Sika offers the Sikacrete®-751 and /-752 3D. These products are easy to mix with water, have a small grain size and with a very light grey colour which make for a very pleasing smooth aesthetic finish. Sika is working closely with many equipment partners to validate the 1-components on various types of equipment, as well as developing new products.

The Sikacrete®-7000 and /-7100 3D is Sika’s award-winning 2K system combining a gantry equipment and highly accelerated printing material in a unique turnkey solution. The automated system utilizes several Sika technologies to enable fast, precise, and high-quality printing. The gantry system was developed by Sika and is fabricated under license with our partners. It consists of a patented mixing station, pump, gantry, patented printing head computer, and software, plus the specially developed Sikacrete® 3D ink for printing.

Sika Automotive

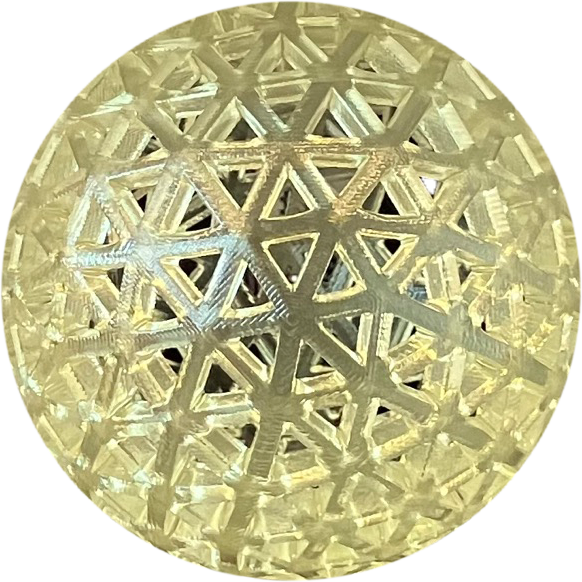

With a full suite of bonding, damping, sealing, and reinforcing solutions, Sika is a key development partner for both automotive OEMs and suppliers. Passengers enjoy a quiet ride, and this can be achieved by sealing common noise transmission paths in vehicle body cavities with our reactive materials – proprietary adhesives and expandable materials – that can be printed. Additive manufacturing is an effective solution for functional and performance testing, design optimization and rapid prototyping. Printed solutions are used during the design and development phase of injection-moulded parts for the automotive industry. Parts can also be designed specifically for additive manufacturing, which brings benefits in terms of design freedom and manufacturing speed: a smart way to reduce the tooling costs for small series vehicles!

Sika Advanced Resins solutions for model and mold design

Sika's 3D processes and materials are used as early as the creative and design phase. The data is converted directly into a 3D dimensionally stable polyurethane solid model. This can then be manufactured into the final model using shaping processes. The data obtained can then be used to design the molds for the finished parts.

Sika Thermoplastic Systems

Thermoplastic materials change into a plastic range when heated and thus become processable. They resolidify upon cooling. Sika’s thermoplastic solutions encompass various materials (like PP, PVC, and PE). These solutions are designed for long service life and withstand the everyday occurrence of standing water and other factors such as radiation, pollution, wind, hail, snow, and the growth of biological organisms. Working with Sika thermoplastic materials means focusing on sustainable, durable solutions and thus on a higher-yield material choice.

Visit us at Hall 12.1 / Booth B88 to see our latest technologies, solutions, products, and trends

![]()