Sehen Sie, wer alles dabei ist oder erstellen sich Ihre eigene Merkliste. Nutzen Sie die Filtermöglichkeiten, um eine Ausstellerliste zur jeweiligen Produktgruppe zu erhalten.

Ishida Europe Limited

Adresse

Ishida Europe Limited

Woodgate Business Park

11 Kettles Wood Drive

Birmingham

B32 3DB

Great Britain and Northern Ireland

Telefon+44 121 607 7700

Entdecken Sie mehr von uns

Über uns

Ishida is a world leader in the design, manufacture and installation of end-to-end weighing, packing and safety solutions for the food industry, helping manufacturers increase automation and compliance, reduce cost and downtime, increase operational efficiencies and brand protection, and maximise profits.

With an installed global base well in excess of 100,000 industrial machines, covering a huge number of applications and end markets, the company is the undisputed world market leader for multihead weighers and one of the leading global suppliers of snack food bagmakers, X-ray inspection systems, checkweighers, graders, traysealers, leak detectors and Industry 5.0 solutions.

Ishida Europe’s product range for meat, poultry, fish, seafood and plant-based protein industry includes:

- Multihead weighers for free flowing or semi-sticky products

- Screw feeder and fresh food weighers for very sticky protein

- Filling-, Distribution and Topping Systems

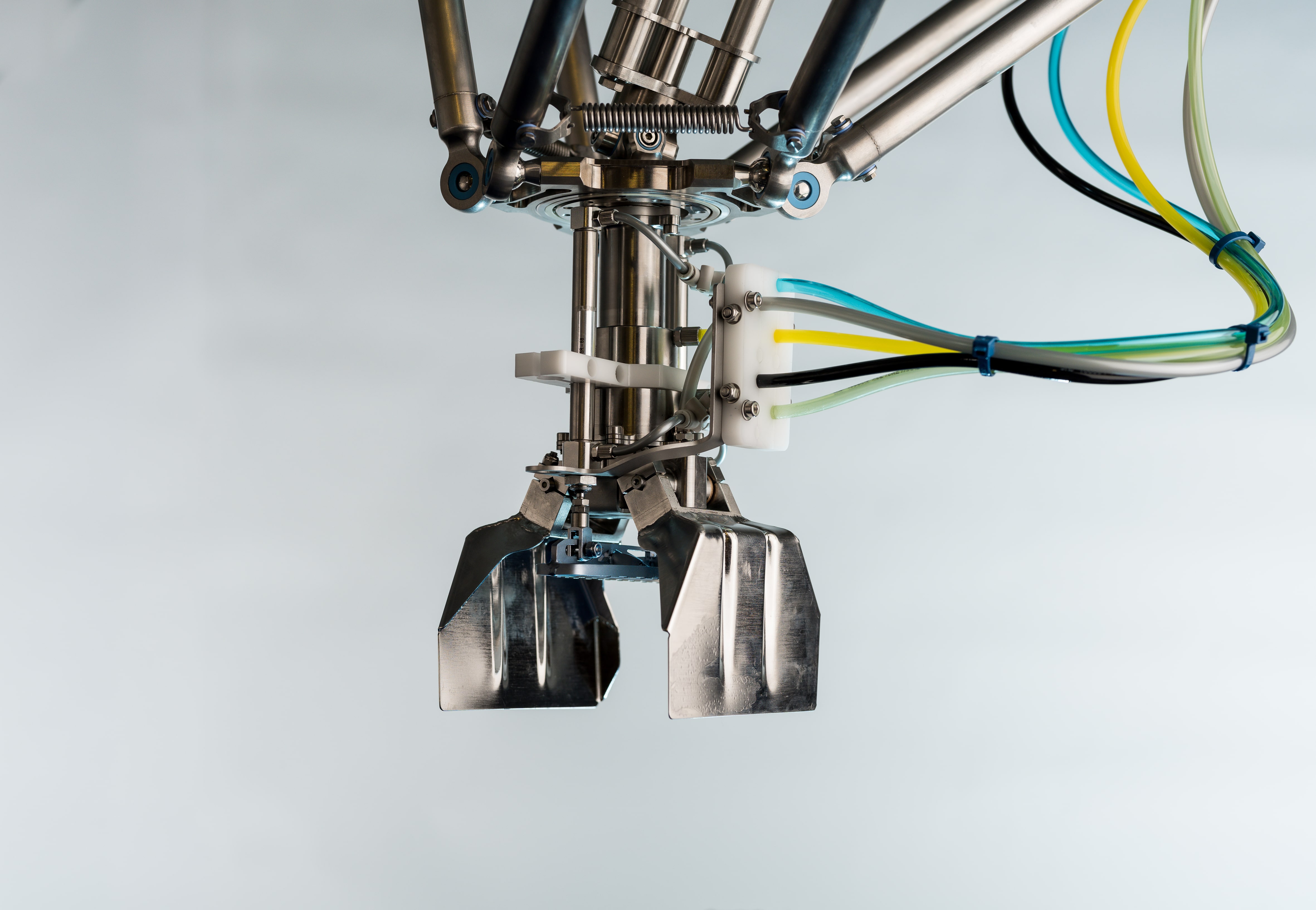

- RobotGraders and FLEX-Graders

- Traysealers including denesters

- X -ray inspection systems including bone detection

- Seal integrity testers with optional vision systems

- Ishida AirScan leak detectors for MAP

- Checkweighers with optional integrated metal detectors

- Weigh-Price-Labellers

- Pick-and-place systems for end-of line automation

- Wall-to-wall solutions

- Industry 5.0 solutions (Ishida Sentinel 5.0)

Unsere Produktgruppen

- Tray sealers

- Vacuum packaging equipment with gas

- Check weighing scales (including higher-load check scales)

- Composite weighing systems

- Manual/automatic weighing and labelling systems

- Robotics and gripping technology

- Foreign matter detectors

- Metal detectors and X-ray machinery

- Designing and planning of slaughterhouses

- Planning and projecting of meat and alternative proteins production plants

Keywords

- MAP

- Weighing

- Multihead Weighers

- Quality Control

- X-ray Inspection

- Tray Sealers

- Wiegen

- Mehrkopfwaagen

- Qualitätskontrolle

- Röntgenkontrolle

Unsere Produkte

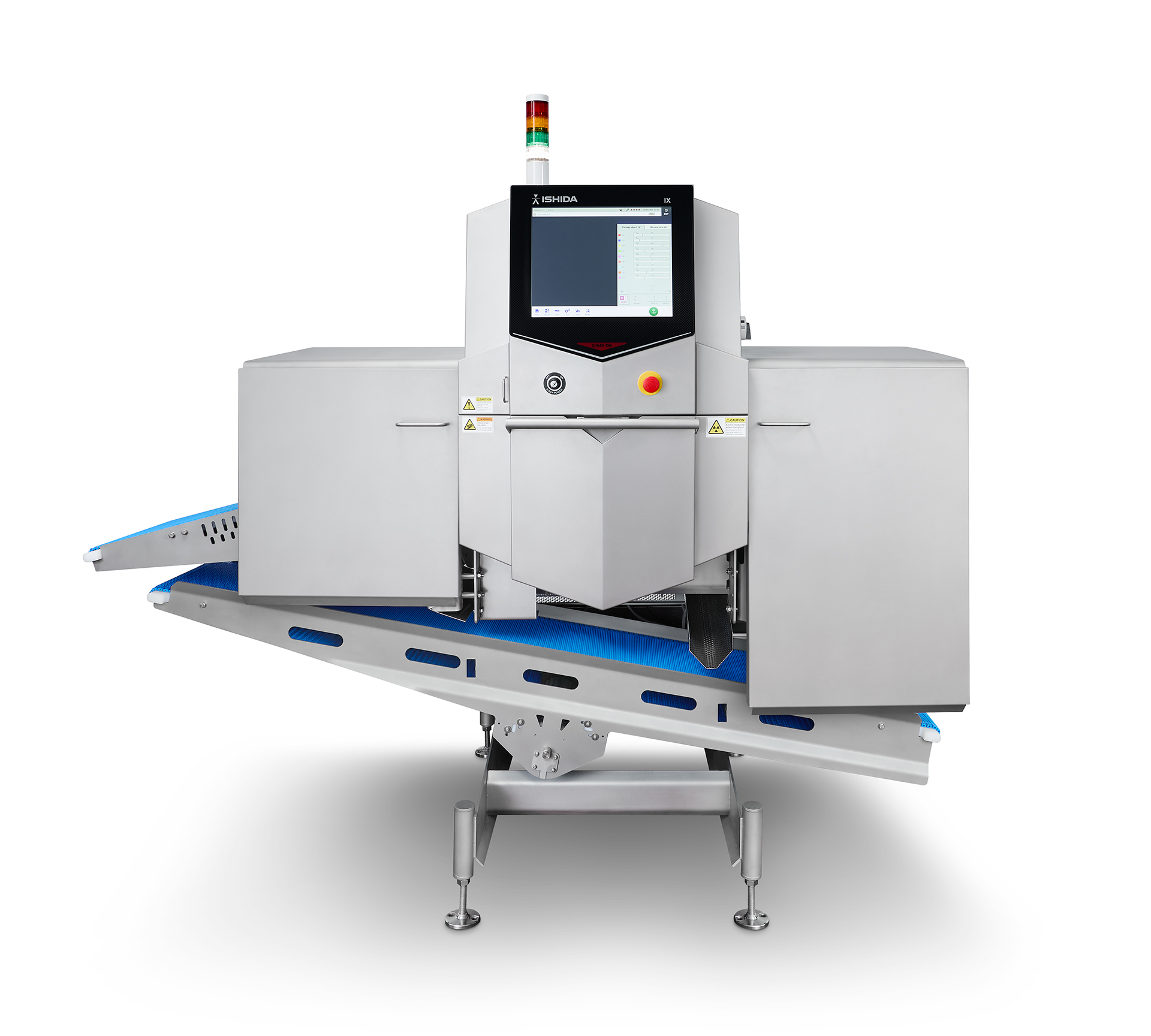

IX-PD-POULTRY: Best-in-class X-ray inspection for high-volume poultry production lines.

Key benefits:

- Integrated dual lane X-ray inspection of chicken fillets at up to 400 pieces per minute.

- IX-PD (Photon-Counting Dual-Energy) technology directly converts X-rays into electrons. This produces ultra high-resolution images to detect wish, rib and fan bones and very small foreign bodies (such as steel wires) with near 100% detection rates.

- The IX-PD's outstanding ability to recognise the difference between food and low-density contaminants, reduces false detections, allowing companies to maintain stringent quality control procedures without compromising on throughput.

- Also ideal for inspecting uneven and overlapping products.

- Integrated re-circulating conveyor to remove and rework rejected product.

- Service offering for X-ray machines delivers a guaranteed Total Cost of Ownership (TCO) of less than 3% per annum over a 5-year period

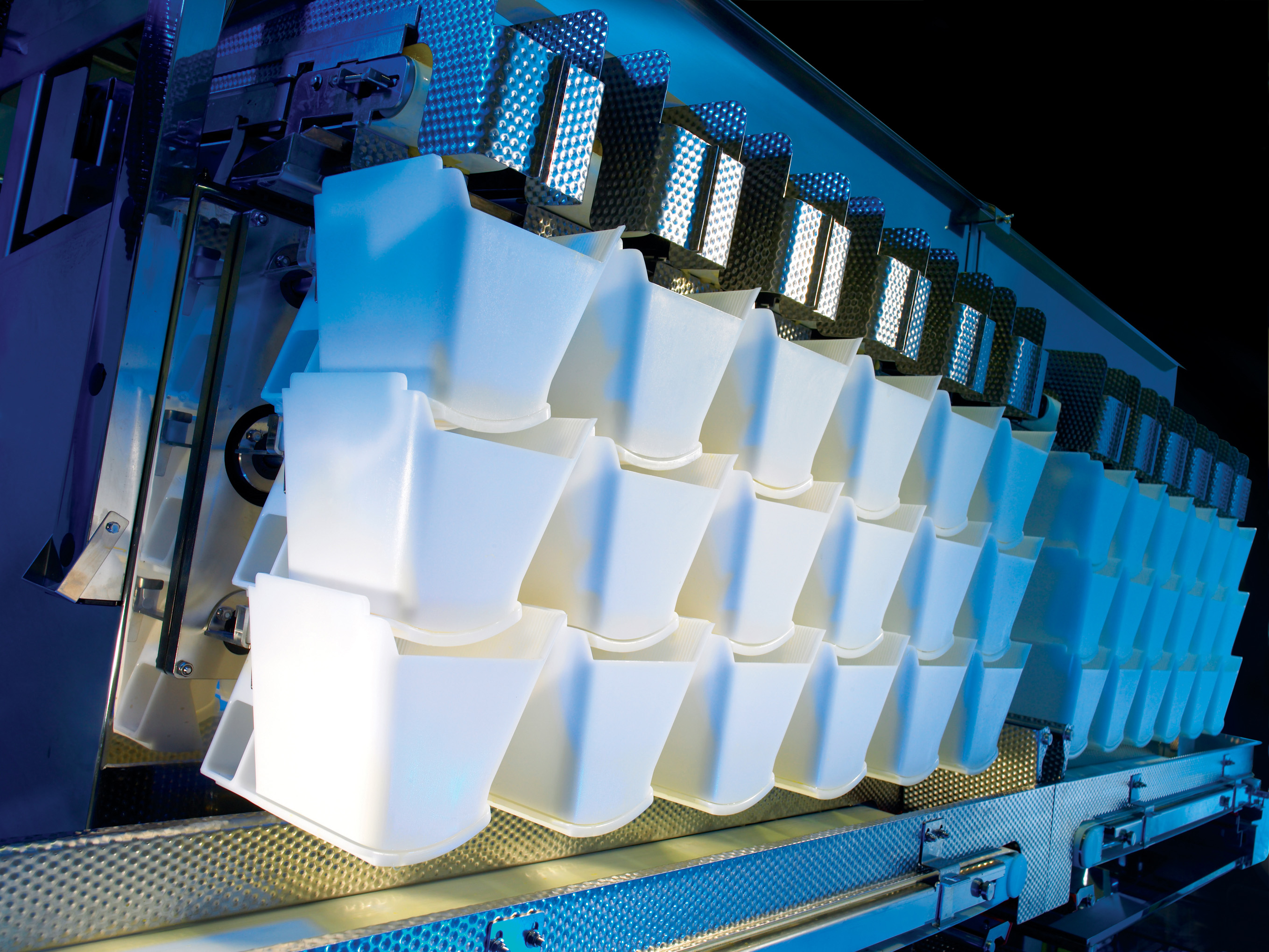

Screw feeder weighers for sticky fresh food

Key Benefits:

•Screw feeders provide powerful, controlled, fully automatic weighing at up to 55 wpm (14 head model) and 90 wpm (20 head model)

•Ideal for sticky products (such as meat and poultry) which cannot be moved by feeder vibration or when manual product feeding is not economically viable

•Hopper sizes and anti-stick contact parts adaptable to suit your application

•High weighing accuracy and efficiency using advanced combination calculation software, 5-stage digital filtering and refined anti-floor vibration, contributing to the reduction of food waste

•Pre-configured for Smart Factories: Ishida Sentinel Reporting Pack, included free of charge for life, provides instant visibility of live machine performance from anywhere in the world

Linear multihead weighers for fresh, sticky and delicate products

Key Benefits:

•The Ishida Fresh Food Weighers are ideal for fresh and marinated meat, poultry, ready meals and plant based protein products

•Belt feeders and anti-stick hoppers with scraper gates prevent build up of sticky products

•All hoppers are equipped with scraper gates for decisive emptying and greater accuracy

•Cuts giveaway to less than 1% of pack weight and reduces labour costs by typically three operators per shift

•Compact dimensions ideal for factories with space or height restrictions

•Waterproof, hygienic design and easy to remove contact parts allow for thorough cleaning and minimise downtime between production runs

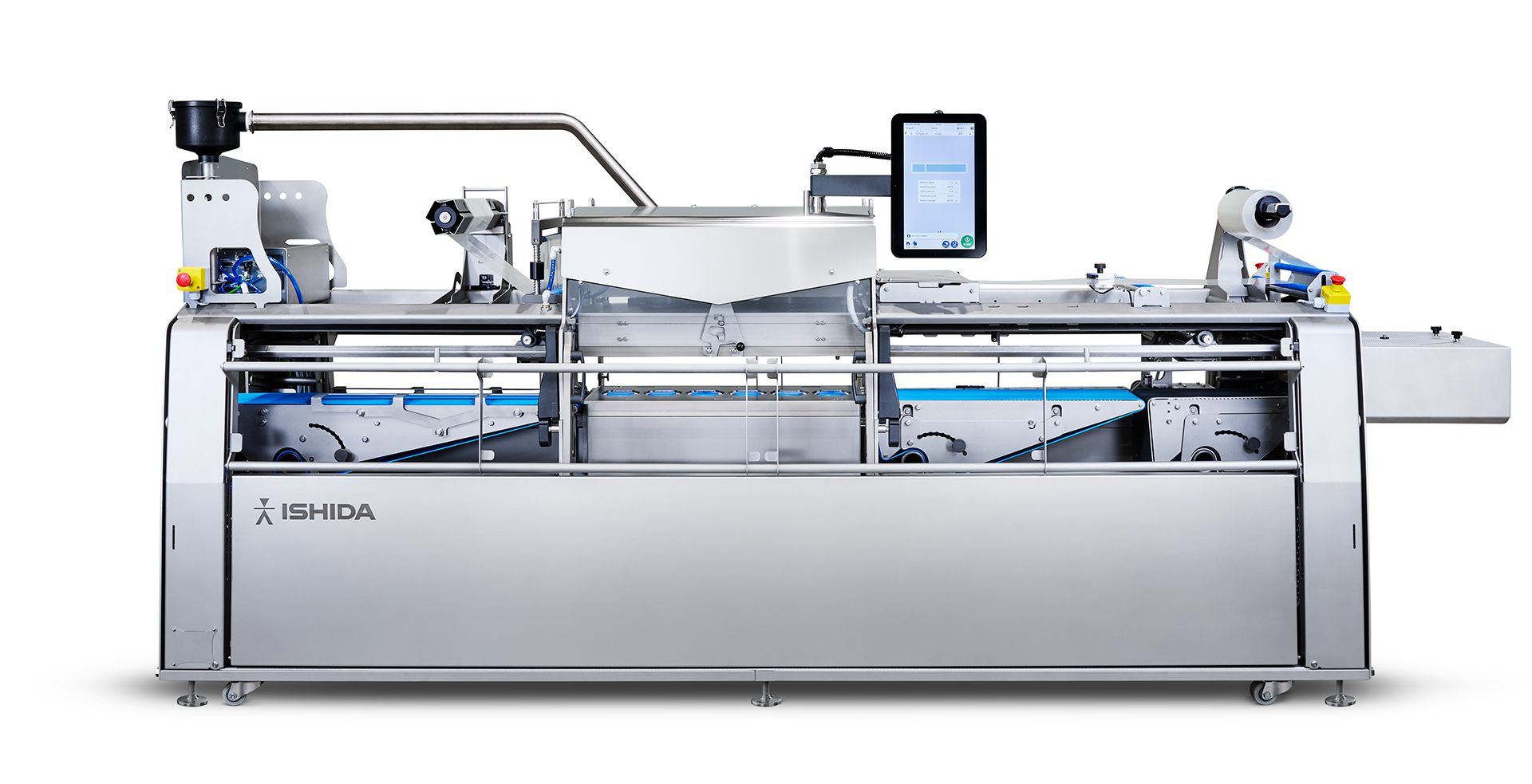

QX-800: New high performance tray sealer for high-volume production lines

Key benefits:

More performance

- 66% increase in cycle speed (up to 17 MAP cycles = 85 trays per minute for a 5-tray tool) helps to meet the demands of high-capacity food production.

Compact design

- 46% reduction in size (incl. a 44% reduction in machine weight) saves valuable floor space.

Energy efficient

- 50% reduction in power consumption

- changing from pneumatic to more efficient servo motor technology has minimised compressed air requirements to significantly cut energy cost

- a focus on the thermo-performance of the tool has removed the need for water cooling.

Perfect control

- A new tray delivery and transfer system allows a smooth tray and product handling to ensure excellent sealing accuracy and spillage free product transfer.

- A unique tool change system allows tools to be changed within 10 minutes without the need for manual handling equipment.

Sustainable

- Can handle cardboard trays, mono-materials and innovative paper film to support the use of sustainable packaging.

QX-500: New ultra compact, high performance Traysealer: More performance with less space!

Key benefits:

Ultimate performance:

- 66% increase in cycle speed (up to 17 MAP cycles per minute = 54 trays per minute for a 3-tray tool) helps to significantly increase production capacity.

Compact design:

- 46% reduction in size (incl. a 44% reduction in machine weight) saves valuable floor space.

Energy efficient:

- 50% reduction in power consumption

- changing from pneumatic to efficient servo motor technology has minimised compressed air requirements, which significantly cuts energy cost

- a strong focus on the thermo-performance of the tool has removed the need for water cooling and thus the need for a water chiller.

Precision control, handling and rapid tool change:

- A new tray delivery and transfer system allows smooth tray and product handling to ensure excellent sealing accuracy and spillage free product transfer.

- A unique tool change system allows tools to be changed within 10 minutes without the need for manual handling equipment.

Sustainable:

- Can handle cardboard trays, mono-materials and innovative paper film to support the use of sustainable packaging.