Suchen und Finden – unser Anbieterverzeichnis bietet mit den umfangreichen Profilen der Formnext-Aussteller einen umfassenden Überblick über die Hersteller und Lieferanten sowie neueste Lösungen und Produkte für den industriellen 3D-Druck.

Laserline GmbH

Brake Disc Cladding

Zum Produkt

LDFblue - Blue Diode Lasers

Zum Produkt

Brake Disc Cladding

Zum Produkt

LDFblue - Blue Diode Lasers

Zum Produkt

Brake Disc Cladding

Zum Produkt

LDFblue - Blue Diode Lasers

Zum ProduktAdresse

Laserline GmbH

Fraunhofer Str. 5

56218 Mülheim-Kärlich

Germany

Telefon+49 2630 9640

Fax+49 2630 9641018

Entdecken Sie mehr von uns

Folgen Sie uns auf

Über uns

Laserline is one of the pioneers in diode laser technology, and played a significant role in achieving a breakthrough with this laser type. Founded in 1997, the company grew within only a few years to becoming an international leading developer and manufacturer of diode lasers for industrial applications. As of today, about 7,500 Laserline diode lasers have been delivered worldwide. Laserline currently employs 400 people and has international subsidiaries on the American continent (USA, Brazil, Mexico) and in Asia (Japan, China, India, South Korea) as well as sales partners in Europe (France, Italy, Great Britain) and in the Asia-Pacific region (Singapore, Taiwan, Australia). The German company is focused on sustained growth, and by setting up its headquarters on company premises in Mülheim-Kärlich close to Koblenz, it sets the spatial conditions for future expansion in terms of development and production.

Laserline diode lasers can be found in a wide variety of different sectors and application areas. Typical application areas are classical forms of metal processing, as in welding, brazing, hardening or softening, as well as realization or repair of coatings. Furthermore, Laserline diode lasers have been established for plastic welding, cladding, additive manufacturing (metal 3D print) and welding of fiber composites. With the worldwide first blue cw high power diode laser (445 nm), Laserline now also enables controlled heat conduction welding of copper, cladding and additive manufacturing.

Users can be found mainly in the automotive industry, engineering, as well as tool and mold-making. In aerospace and heavy industry, Laserline diode lasers are also in use.

The power range of Laserline diode lasers reaches well into the multi-kilowatt area. As today’s standard, lasers with up to 45 kW power are available; in test runs, 60 kW has already been realized. The exceptionally high wall-plug efficiency of over 50 percent is groundbreaking. For applications with high demands for focusability, diode lasers with a beam converter have been developed that offer beam qualities from 8 to 4 mm·mrad. Laserline diode lasers are both durable and low-maintenance, and are characterized by a compact and mobile design. This is possible because of the innovative Laserline diode cooling technique which makes flexible application scenarios possible. Furthermore, Laserline offers diode lasers as 19-inch rack-mount and customized laser designs. At its own application lab, industry specific solutions are developed, possibly realized as prototypes, and tested comprehensively. Additional components like processing optics, scanners, beam switches and monitoring systems round out the company’s portfolio. Training, service and maintenance contracts are offered to operators. In the case of malfunction, a 24/7 service hotline and teleservice with remote diagnosis are available.

Unsere Produktgruppen

- AM systems

- Ancillary process systems

Keywords

- diode laser

- additive manufacturing

- powder bed fusion

- laserline

- cladding

Unsere Produkte

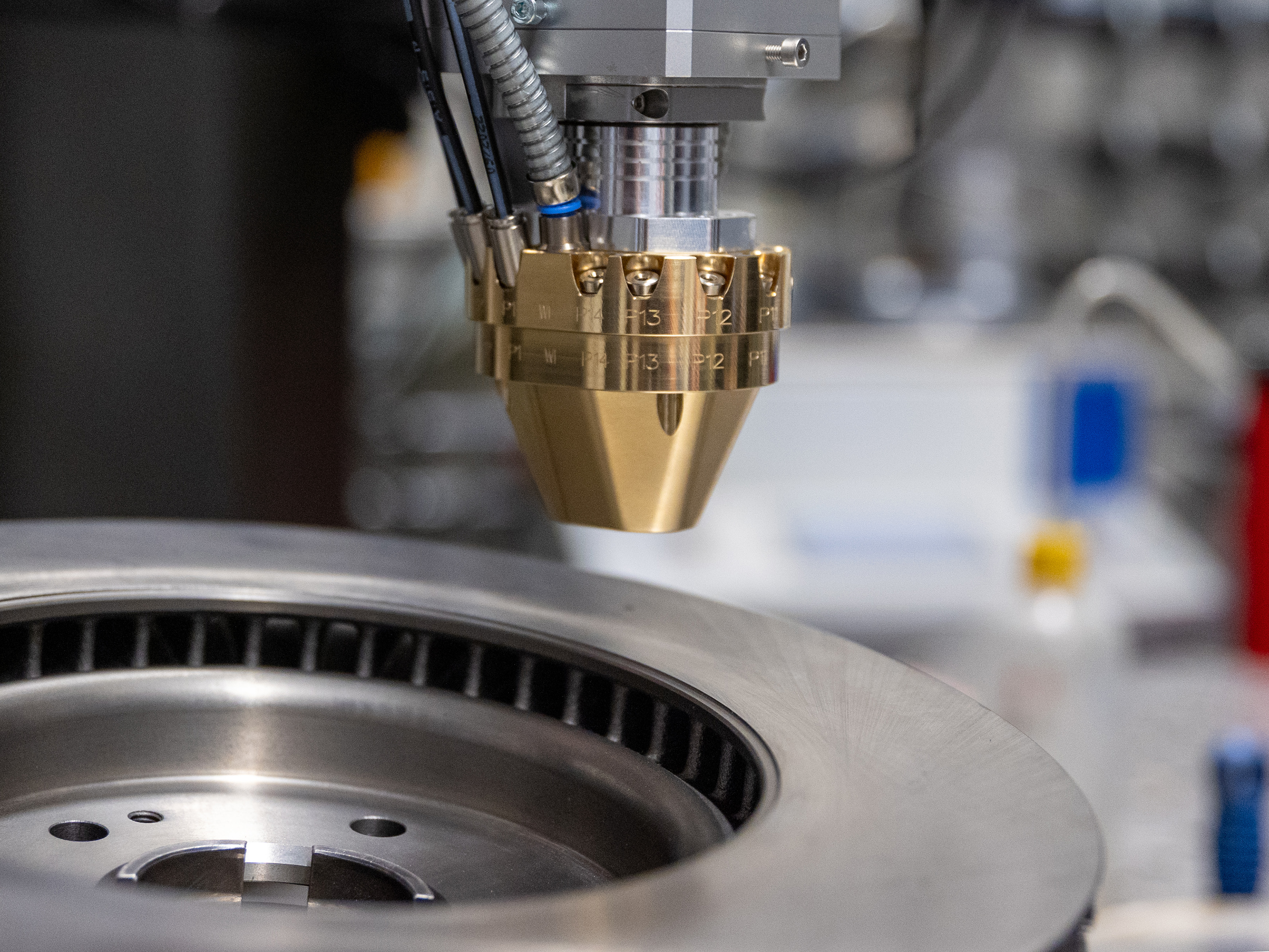

Brake Disc Cladding

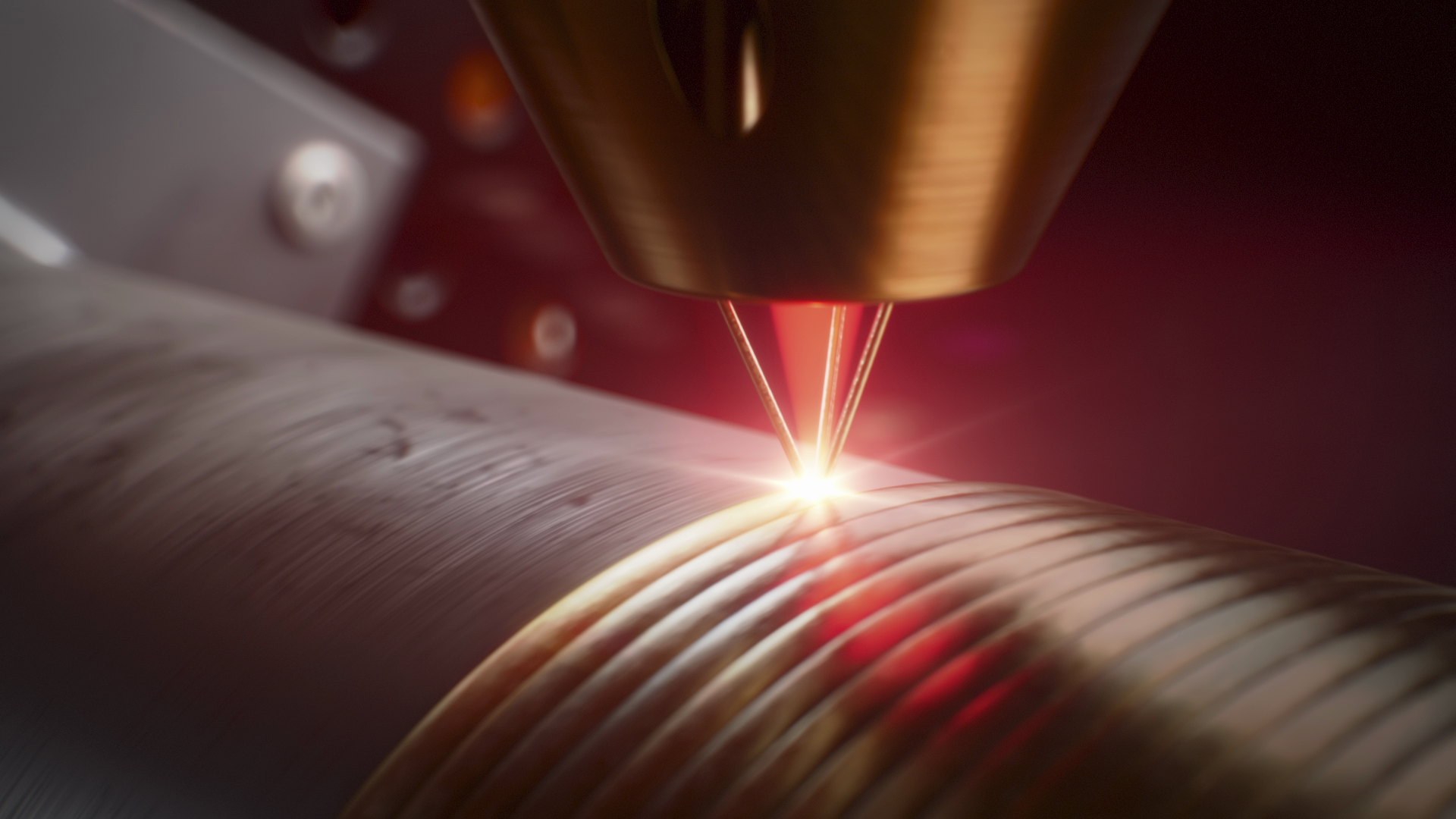

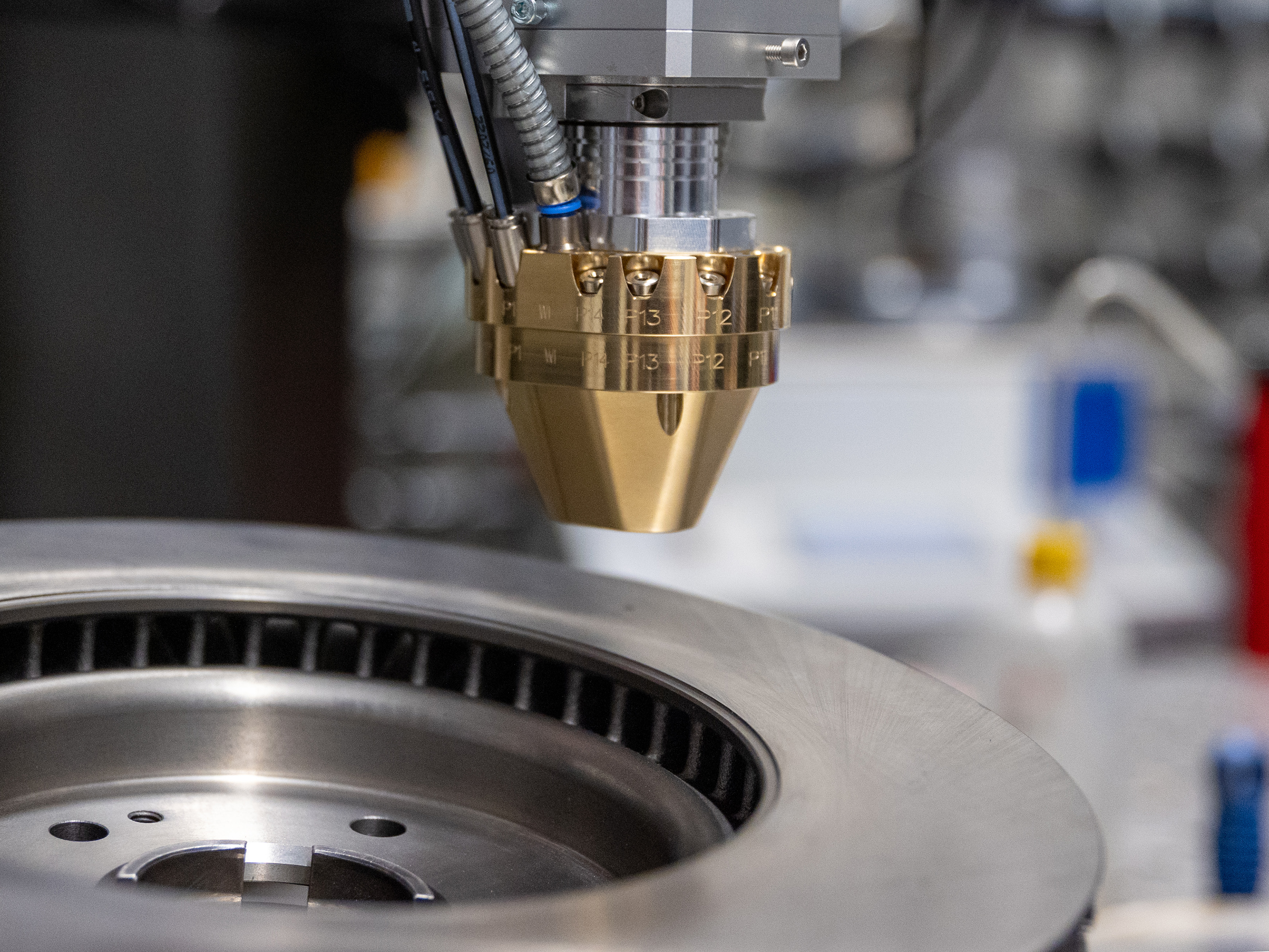

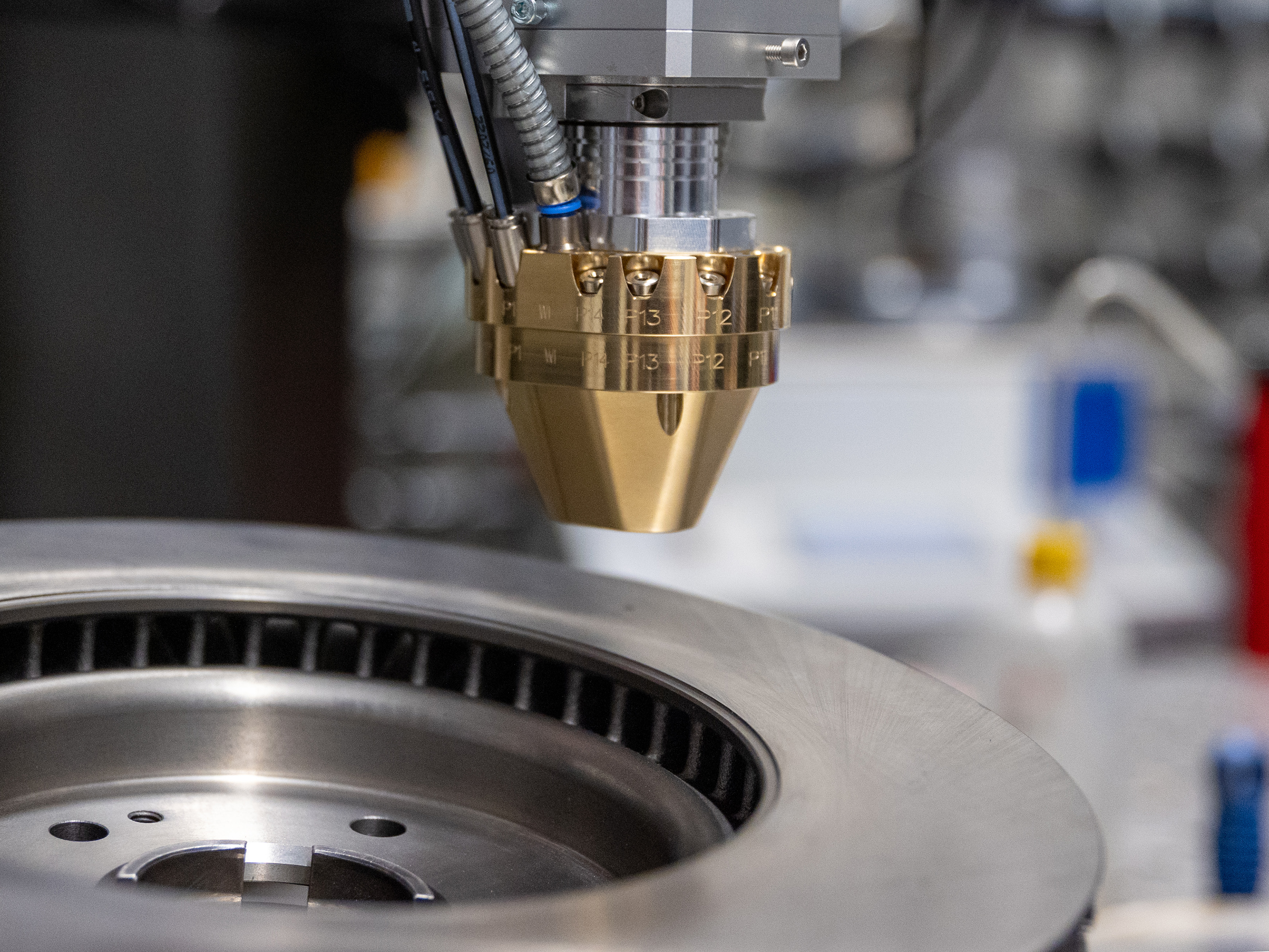

30 kW Laser Power - Cladding technologies using diode lasers enable the fast manufacturing of low-wear gray cast iron brake discs and lead to a significant reduction in fine dust emissions of up to 90 percent and an extended service life. This makes an important contribution to environmental protection and sustainability. Thanks to fast and effective cladding processes and the possibility of demand-oriented material cost control, laser-coated brake discs are also of interest to the mass market and are available in all price segments.

High-Speed Laser Cladding with TwinClad Optics - The OTS-5 TwinClad Optics system introduces a solution designed for high-speed cladding applications, such as brake disc cladding. Its innovative pre-beam technology cleans and tempers the workpiece surface, preparing it for superior coating adhesion. With a flexible, durable nozzle design, TwinClad allows precise control over spot geometry, powder quantity, and nozzle composition, making it adaptable to diverse production requirements and delivering consistent, high-quality cladding results.

Web: https://www.laserline.com/en-int/news-detail/the-brake-for-less-fine-dust/

Web: https://www.laserline.com/en-int/claddingoptic/

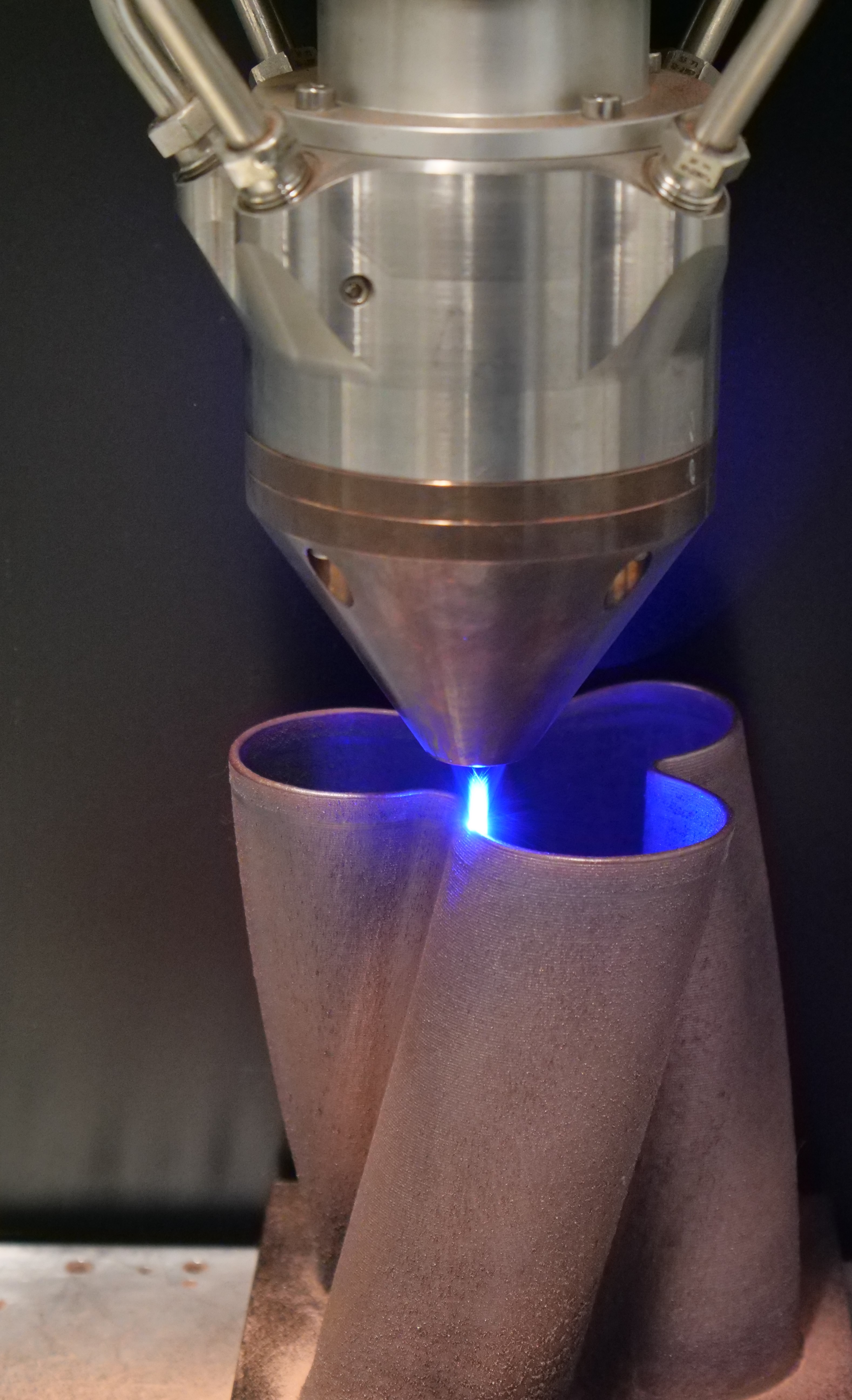

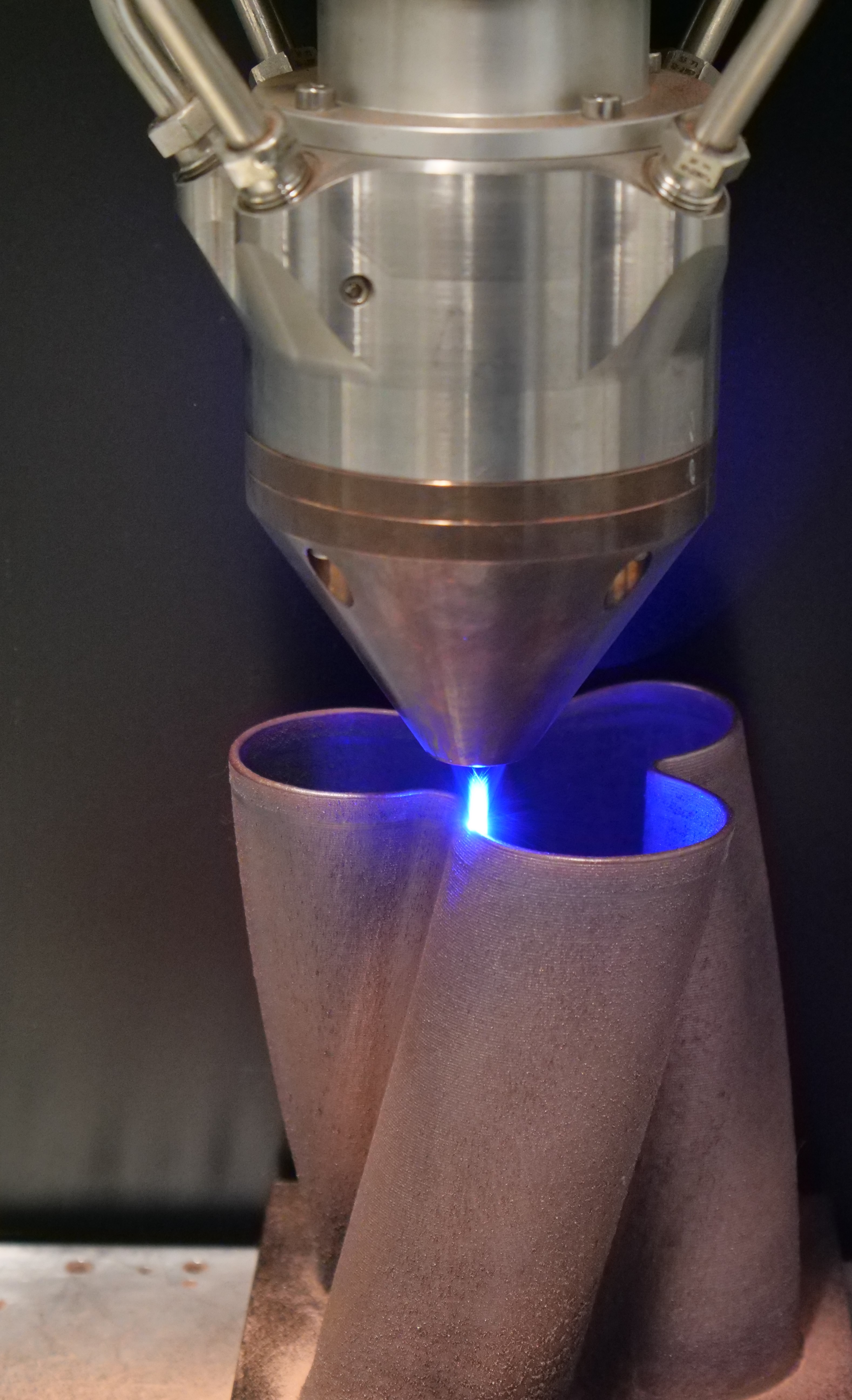

MultiWire Cladding – Direction-Independent Application

MultiWire laser cladding offers a highly efficient solution for creating wear-resistant, corrosion-proof surfaces. By using three wires, it achieves higher deposition rates and a direction-independent application. Compared to thermal spraying, this process provides greater durability and, unlike hard chrome plating, poses no health risks. With 100% material efficiency, it supports cost-effective manufacturing and reduces resource waste, making it an optimal choice for sustainable production.

Web: https://www.laserline.com/en-int/laser-multiwire-cladding/

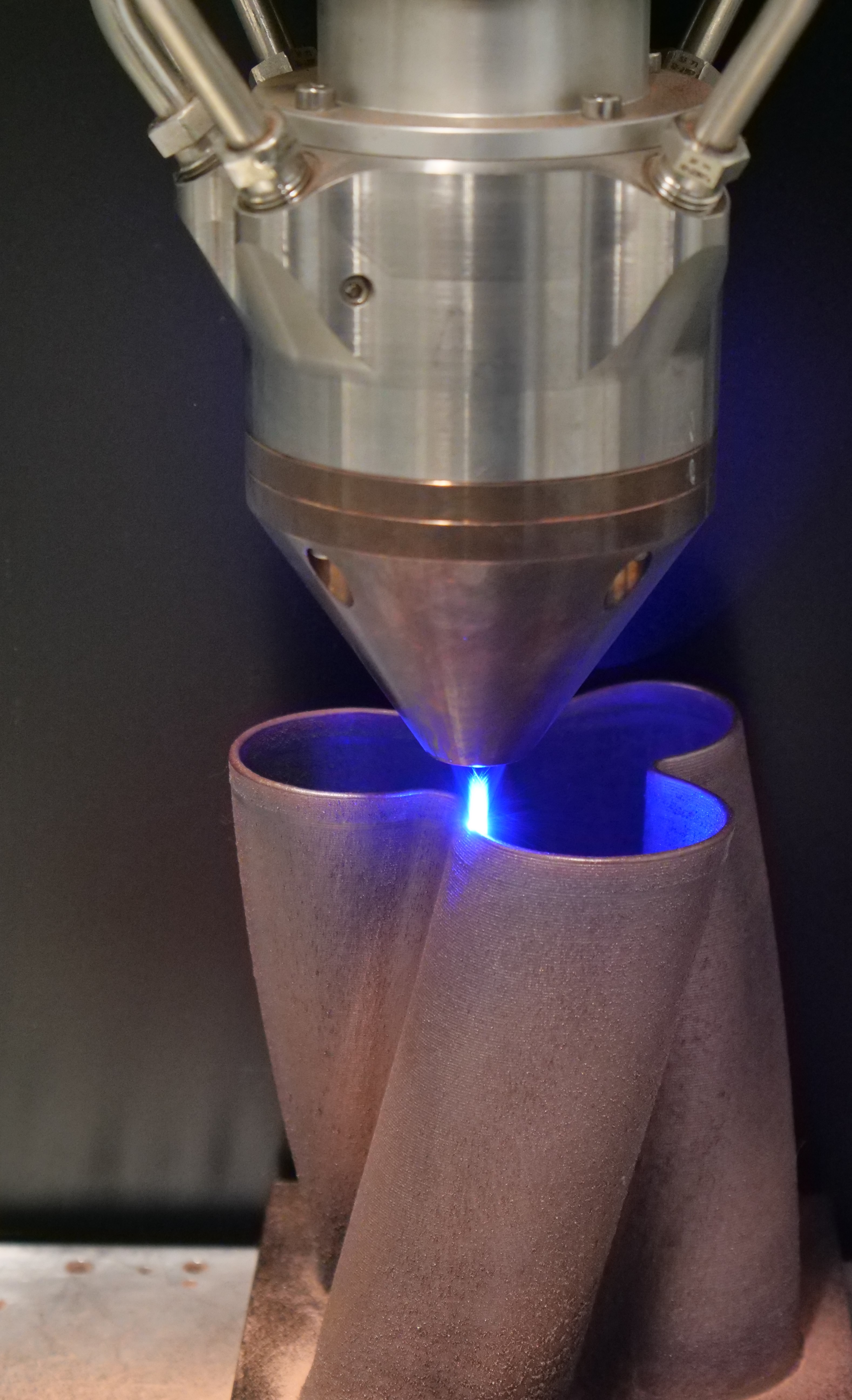

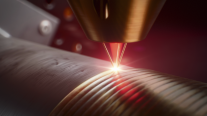

LDFblue - Blue Diode Lasers

Blue High Brightness Laser Source - Laserline’s latest addition to its industrial diode laser portfolio features high beam qualities of 4mm.mrad and better. This laser with a high focusability is ideally suited for precision applications, including 3D metal printing in powder bed processes. The system provides an industry-proven design with a familiar Laserline interface and global service support, ensuring reliable, high-performance additive manufacturing.

6 kW Blue Diode Laser - The blue diode laser revolutionizes the processing of copper, gold and its alloys in various ways. The generation of up to 6 kW (cw) laser power in the 445 nm wavelength range is unique for industrial lasers. This wavelength is ideal for the processing of highly reflective materials since its higher absorption allows significantly lower intensities and larger laser spots. Up to 6 kW laser power supports heat conduction as well as keyhole welding processes, cladding and additive manufacturing.

Web: https://www.laserline.com/en-int/blue-diode-laser/

LDF Series – Up to 45kW Laser Power

Laserline is the international leading manufacturer of diode lasers for industrial materials processing and sets a new benchmark for high power diode lasers: The modular LDF VG6 series is versatile in use, offers 45 kW laser power in less than one square meter footprint and an electrical efficiency of over 50 percent – even at high beam qualities. Whether power, internal or external cooling system or system interfaces: The LDF series can be individually configured to changing requirements.

Web: https://www.laserline.com/en-int/ldfseries/

Diode Laser System LDM – Compact, Powerful and Reliable

The 19-inch rack mount technology offers a significant simplification of the laser integration in machines or systems. The LDM module combines the laser head, the power supply of the diodes, the controller for monitoring, as well as the cooling system. The innovative, small footprint design allows the LDM diode laser to be easily integrated within the production area. The laser requires no additional space and is therefore perfect for OEM applications.

Web: https://www.laserline.com/en-int/ldmseries/