Suchen und Finden – unser Anbieterverzeichnis bietet mit den umfangreichen Profilen der Formnext-Aussteller einen umfassenden Überblick über die Hersteller und Lieferanten sowie neueste Lösungen und Produkte für den industriellen 3D-Druck.

Laser Zentrum Hannover e.V.

Über uns

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. The LZH is dedicated to applied research in the field of photonics and laser technology and offers individual and customized solutions with its smart photonics applications. At our institute, scientists and engineers work in an interdisciplinary way to use light for innovation: From the development and production of specialized laser systems to process developments for a wide range of laser applications for industry and science.

In the field of additive manufacturing, among others, we identify and initiate trends, thus significantly contributing to the advancement of science, economy, and industry.

The LZH is supported by the Lower Saxony Ministry of Economics, Transport, Building and Digitalisation.

Unsere Produktgruppen

Keywords

- 1. Prozessentwicklung

- 2. Forschung und Dienstleistungen

- 3. Sonderanlagen

Unsere Produkte

Additive Manufacturing with Metals

In addition to the familiar powder- and wire-based processes, the Laser Zentrum Hannover is working on novel process and material combinations and on exploring the limits of what can be printed.

With Powder Bed Fusion (LPBF/PBF-LB/M), we work with industrially proven titanium, CrNi, copper, and wear and corrosion-resistant steel alloys. In addition, we are establishing 3D printing processes for magnesium alloys, Kovar, regolith, and other special materials.

Laser-based deposition welding

As experts in deposition welding, one of the things we are working on is the resource-efficient repair of cost-intensive components using powder-based deposition welding. Ware researching single-crystal deposition welding. With various nickel base superalloys we work on repairing engine components and transfer this method to technical applications. Also, we are developing future-relevant processes for thermal and structural components made of different material combinations and engaged in alloying and dispersing ceramic particles and grading with tungsten carbides.

In the field of deposition welding with wire as the filler material we develop processes with structure sizes in the micrometer range up to XXL products with several tons of component weight. We use laser-wire deposition welding and laser-assisted processes with and without arc and with one or two wires. We work with wire diameters from 0.1 mm to 1.6 mm and print, for example, wear-resistant steel alloys such as 100Cr6. The processes are suitable, for example, for thermally and mechanically highly stressable prototypes, tool and mold making and for products/small series. We are also working on producing semi-finished products for subsequent forming.

New materials with new possibilities

New materials with new possibilities are crucial for innovative applications in lightweight construction or medical technology. We research processes for these materials and characterize them for additive manufacturing. For oxygen-affine materials, for example, we develop plant and machine technology with oxygen-free environments. For special materials, we adapt the processes to the application. In addition, we work with statistical experimental design to smartly expand process windows and investigate the interrelationships of various target variables. We work with Titanium alloys, Magnesium alloys, Kovar, Invar, Nickel-titanium alloys, Nickel superalloys, Copper alloys, Regolith and with wear and corrosion-resistant steel alloys.

Additive manufacturing in special environments

Whether underwater or under varying gravity conditions, we make additive manufacturing possible even under challenging environmental conditions. To this end, we are developing the necessary process and system technology. This must also function robustly under different pressure conditions to implement repairs or add-ons to maritime systems with additive manufacturing in the future. To make this possible, we take into account the water depth and the ambient temperature and the nature of the materials present.

Another focus of our work is the cross-scale and hybrid Additive Manufacturing. For complex components, we combine several processes to manufacture across scales. This results in components that combine the advantages of several manufacturing techniques. For example, our scientists print large basic bodies and supplement them with filigree structures. In hybrid manufacturing, we work with different materials to apply wear or corrosion protection. Also, our team adjusts the properties of the manufactured structures with in-situ alloys. Furthermore, we investigate graded structures to optimize material transitions and make scale-independent and modular production technology possible

Our Services

As a business-oriented research institute, we operate independently of manufacturers and maintain confidentiality while bringing innovations into your company or further developing them with you.

Contract research and development

Do you need a technological solution for your challenge? Then, take advantage of our more than 30 years of experience in applied research and development. We transfer the latest scientific findings from research to your company to secure and increase your competitiveness.

We offer customer-specific processes, systems, and components - from feasibility studies to complete technology transfer, bilateral contract research and development agreement and an exclusive and confidential cooperation, if required based on non-disclosure agreements.

Project Funding

Cooperation projects with partners from business and science can receive financial support from numerous funding bodies at the state, federal, or EU level. Do you have a project idea that you might want to realize with us? Please contact us.

Many funding opportunities are aimed at both large companies and SMEs. We would be happy to check with you whether and which funding opportunities are available for your project.

We offer a comprehensive overview of funding opportunities and many years of experience in the application, implementation, and coordination of publicly funded projects. You can also profit from an extensive network of other possible project partners.

Prototypes and small series

Would you like to check the feasibility of your idea? Or do you need a single piece or a small series? We are happy to support you.

We offer the development of new products and the required processes, do feasibility studies and studies on how your project can be implemented in the best possible way, customized products and solutions, and an extensive infrastructure to put your project into practice such as clean rooms, laboratories, laser facilities, imaging and analysis systems.

Special machines and devices

We develop and construct special machines and devices customized to the needs of our customers. We offer the development and qualification of laser systems, as well as the development of monitoring systems, imaging systems and system and equipment technology. You receive systems and devices customized to your individual requirements and benefit from our expertise from our work in and on research and transfer projects.

Consulting

Do you have an idea or a project and need an independent assessment? As a non-profit research institute, we are exactly the right partner for this.

We advise on feasibility, economic efficiency, process optimization and redevelopment, regulatory affairs for medical products and approval studies as well as on laser and occupational safety. We provide you with manufacturer-independent and neutral advice. You benefit from our wealth of experience from decades of research and development.

Direct orders

You can order a wide range of services directly from us. Feel free to contact us with your request - no matter how small or large.

Among other things we offer measurements of technical and biological samples, laser development, coating and characterization of optics, laser material processing, emission analysis and sample preparation.

Technology Transfer

We develop and research with a focus on your needs. Of course, we also integrate processes and system technology developed by us into your company.

We offer the application-oriented development of processes, system technology, and components and provide close support until the final integration at your site and beyond. Of course we guarantee the trustworthy handling of your data.

Additive Manufacturing with Non-Metals

We are optimizing processes for Additive Manufacturing to open up new applications or are working on establishing new materials to make plastic printing more sustainable. To manufacture components even better and more cost-effectively, we are also working on process stability and component resolution.

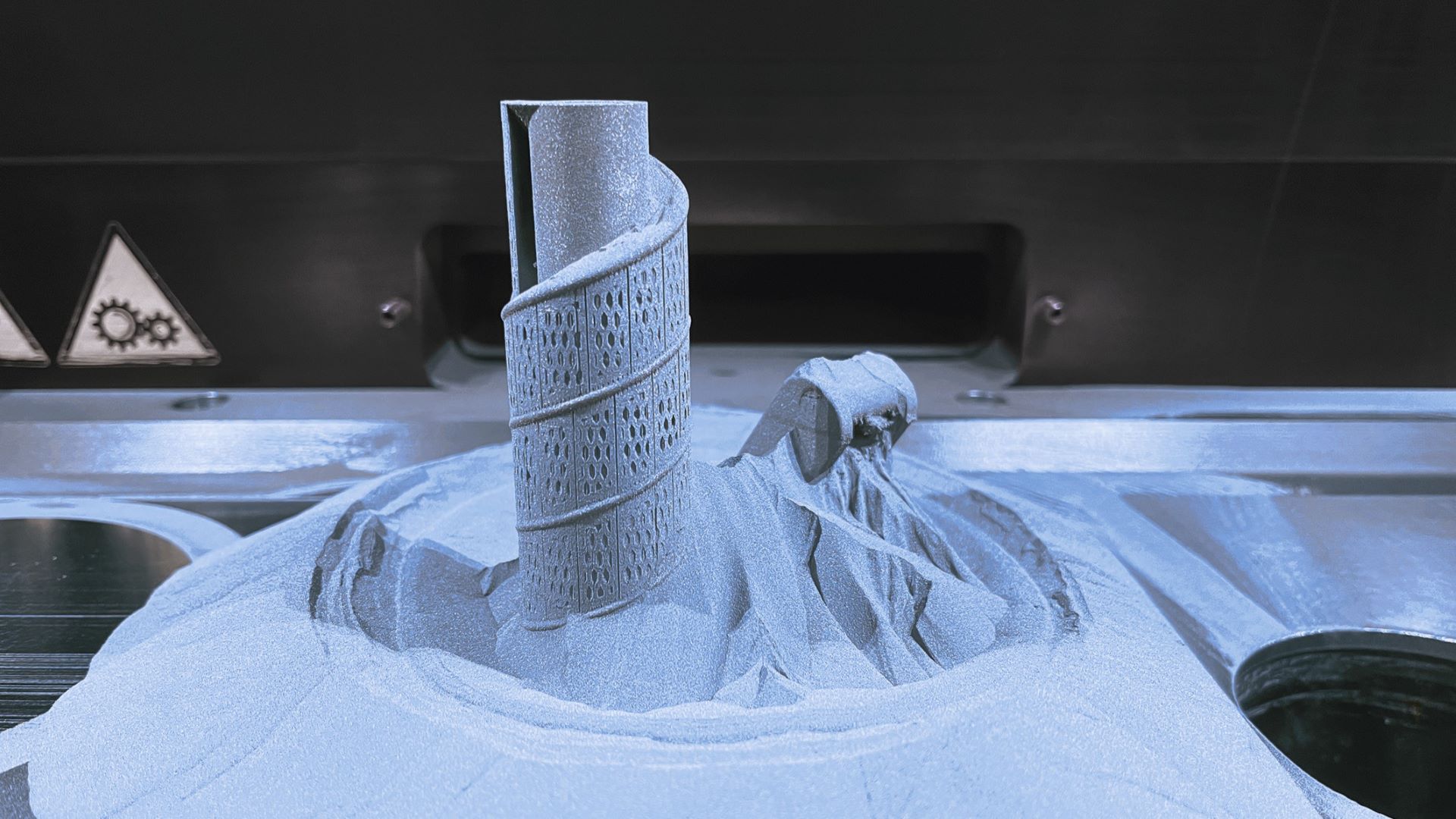

We are working on smart process monitoring systems for selective laser melting (SLS). These should make it possible to intervene in the running process and adjust it if necessary. In this way, we want to prevent heat buildup and make the entire powder bed reliably usable as a printing area. In this way, we want to avoid costly and time-consuming misprints. We continue to develop powder-based additive manufacturing processes with the laser to adapt them for new applications or materials.

In Fused Deposition Modelling (FDM), we focus on topology optimization and process development to qualify new materials for 3D printing. One focus is on sustainable natural fiber-based or compostable materials. With high-performance fiber composite structures, we want to create new manufacturing processes for lightweight construction. We are also working on joining 3D-printed elements through laser transmission welding. Components made by filament printing have many uses, including facade cladding in architecture or as veneers on furniture. We work in particular on fiber composite structure short and continuous fiber-reinforced materials.

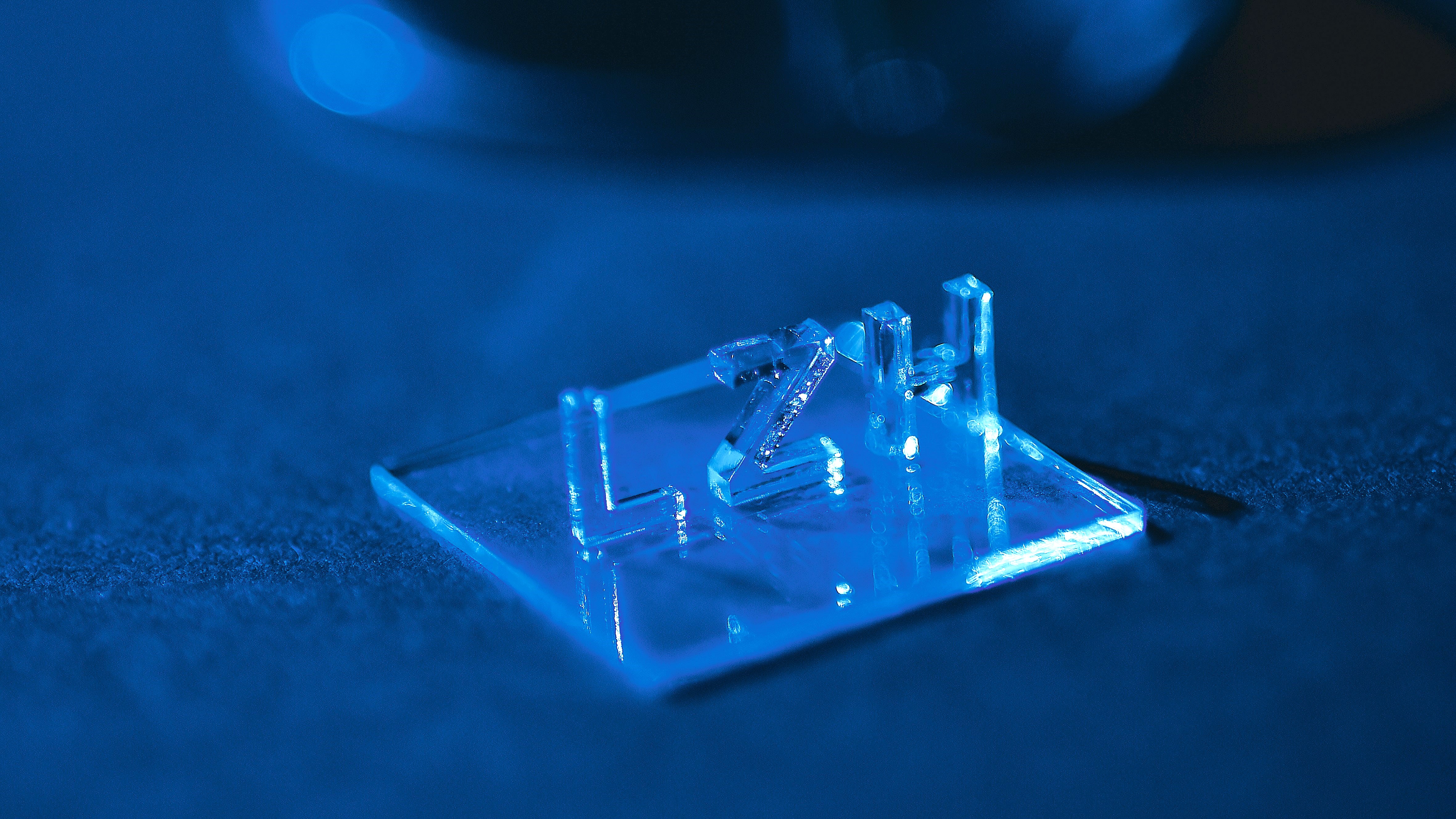

In the field of liquid-based Additive Manufacturing, we develop high-resolution 3D printing processes further to tap their potential for the generative production of multiscale structural parts or even complex components. In addition to laser-based technologies in the polymer bath, such as stereolithography and two-photon polymerization, we use micro-dispensers and the Aerosol Jet as well as hybrid processes. We dispense conductive tracks and optical polymers, for example. Additionally, to expand the potential for industrial use, we are developing strategies for automating process chains.

Multimaterials and new materials

To additively manufacture multi-material components, we are developing processes to combine different materials. On the one hand, the focus is on combining materials of the same type, and on the other hand, on combining metal components with plastics. We are also working on graded materials to flexibly vary the hardness and composition of a component.

To further establish Additive Manufacturing in the industry and to open up new application fields, we are working on and with new materials. To this end, we develop new processes or optimize existing ones. To achieve optimal properties, we analyze and characterize the components in detail and adapt the processes accordingly. We work with: conductive materials, sustainable and compostable natural materials, carbon fibers for fiber composite structures, transparent photopolymers and hybrid materials (organic-inorganic).

Glass and ceramic materials

We develop manufacturing processes further to produce reproducible and automatable glass components with a high level of complexity and optical quality. The Additive Manufacturing of glass, also known as Laser Glass Deposition, has been co-developed by us and enables the automated production of complex structures using a fiber-based process. The focus is on the automation of extensive handling, from handling the raw material to the finished product for standardized, reproducible results. Furthermore, we are working on additive manufacturing of optics and optical components such as ball lenses. We can print on existing components as well as build up independent components layer by layer.

Ceramic and glass materials can be additively processed into components using the powder bed process. In addition to producing complete components, we are researching the targeted modification of electrical properties by dispersing ceramic particles in metal during laser cladding. We are also working on grading with tungsten carbides in the laser coating process to significantly improve the service life of tools.

To set the basis for more applications for the additive manufacturing of glasses and ceramics, we are developing and evaluating processes for materials that have not yet been used for this purpose. The processing of quartz glass and borosilicate glass is of great interest for optics and glass apparatus engineering. For ceramic and glass materials, we are currently developing the processes further. We are also working on enabling additive processing of the widely used soda-lime glass for the first time.